Getting a high-quality plastic part depends entirely on a perfect mold. A flawed mold can cause production delays, wasted materials, and poor product quality. Understanding the manufacturing process is the key to choosing the right partner and ensuring your project’s success. It puts you in control.

The manufacturing of a plastic mold is a multi-step engineering process. It begins with a detailed 3D design using CAD software. Then, high-strength steel is precisely machined using CNC, EDM, and grinding to create the mold’s core and cavity. These components are then expertly assembled, polished to the required finish, and rigorously tested to ensure they produce flawless plastic parts consistently.

The journey from a digital concept to a physical, high-performance mold is one of precision and expertise. It’s a process we’ve perfected over many years at CavityMold. To really appreciate what goes into it, you need to look at each stage closely. Let’s break down the entire process, so you can see how your idea becomes a reality and what to look for in a manufacturing partner.

How are molds manufactured?

The term "mold manufacturing" can sound complex and a bit intimidating. If you don’t have a basic grasp of it, you can’t effectively communicate with your suppliers or judge their skills. Let’s break down the fundamental steps common to most mold-making, giving you the confidence to manage your projects.

In general, molds are made by first creating a detailed 3D design. Then, durable materials like steel or aluminum are shaped with high precision using CNC machining and electrical discharge machining (EDM). After machining, the different components are carefully assembled, polished to the specified surface finish, and tested to ensure they work correctly and produce accurate parts.

The Core Principles of Mold Making

At its heart, making a mold is about creating a negative space—a cavity—that will shape a material into a desired form. This principle applies whether we’re talking about plastic injection molds, die-casting molds for metal, or stamping dies for sheet metal. The first and most critical decision is the mold material. For most high-volume applications, this means choosing the right type of steel. For prototyping or lower volume runs, aluminum is a great option.

The choice between steel and aluminum comes down to a trade-off between durability, cost, and speed. Steel molds are a bigger investment upfront but can produce millions of parts. Aluminum molds are cheaper and faster to make but wear out much sooner. We always start a project by discussing the product’s lifecycle to recommend the right material.

Key Manufacturing Technologies

Once the material is chosen, we use a combination of advanced technologies to shape it.

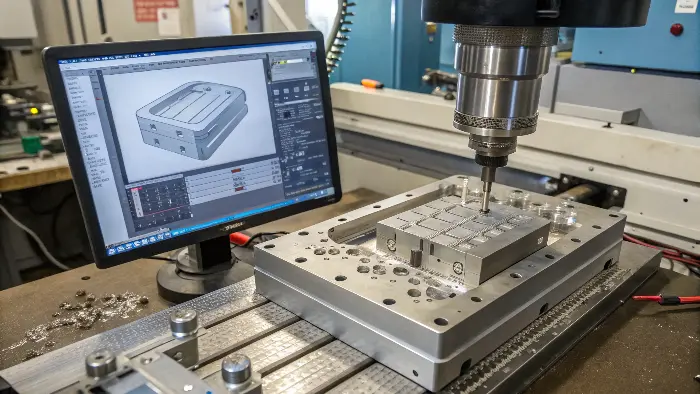

- CNC (Computer Numerical Control) Machining: This is the workhorse of our shop. A CNC machine cuts away material from a solid block of steel or aluminum based on the 3D CAD file. It’s used to create the main shape of the mold’s core and cavity.

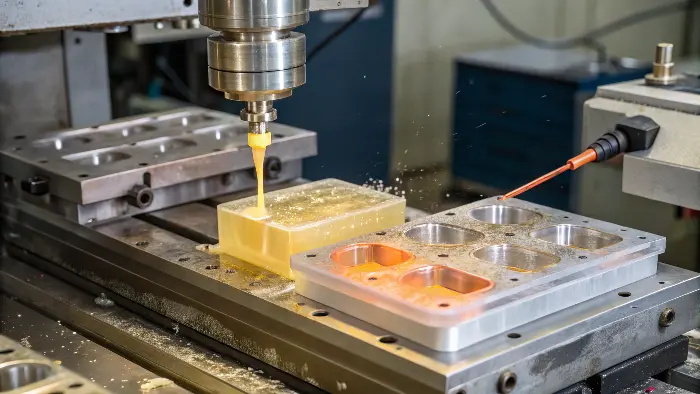

- EDM (Electrical Discharge Machining): This process uses electrical sparks to erode material. It’s essential for creating features that are impossible to do with a traditional cutting tool, like sharp internal corners, deep ribs, or complex textures.

- Grinding: After the main shaping is done, precision grinding ensures all surfaces are perfectly flat and dimensions are exact. This is crucial for the two halves of themold to seal perfectly.

Here is a simple table to help you compare the two main material choices.

| Feature | Steel Molds (e.g., P20, H13) | Aluminum Molds (e.g., 7075) |

|---|---|---|

| Durability | Very high (can exceed 1 million cycles) | Lower (from 1,000s to 100,000s cycles) |

| Cost | Higher initial investment | Lower initial investment |

| Lead Time | Longer to machine and finish | Shorter, much faster to machine |

| Heat Transfer | Good | Excellent, which can reduce cycle times |

| Best For | High-volume mass production | Prototyping and low-volume production |

What is the process of plastic mold manufacturing?

You have approved a final product design, but now you need the physical mold to make it. Any misstep in this critical manufacturing phase can derail your entire production timeline and budget. Understanding the specific, step-by-step process for creating a plastic injection mold removes the mystery and shows the path from a digital file to a functional tool.

The process begins with a Design for Manufacturability (DFM) analysis of the part. Next, the mold is designed in CAD software. Steel blocks are machined for the core and cavity. Components like ejector pins and cooling channels are integrated. The mold is then assembled, polished, and put through a trial run (T1 samples) to validate its performance before production.

The Step-by-Step Journey of a Mold

Creating a high-quality plastic injection mold is a systematic process where every step builds on the last. At CavityMold, we follow a proven workflow to ensure nothing is missed.

Step 1: Design for Manufacturability (DFM) Analysis

Before we cut any metal, we analyze your part design. The DFM report is our first and most important conversation with you. We look for potential issues that could cause problems during molding, such as walls that are too thin or thick, lack of draft angles for easy ejection, or complex undercuts that would require special mechanisms. Solving these issues on the computer saves a huge amount of time and money later.

Step 2: Mold Design

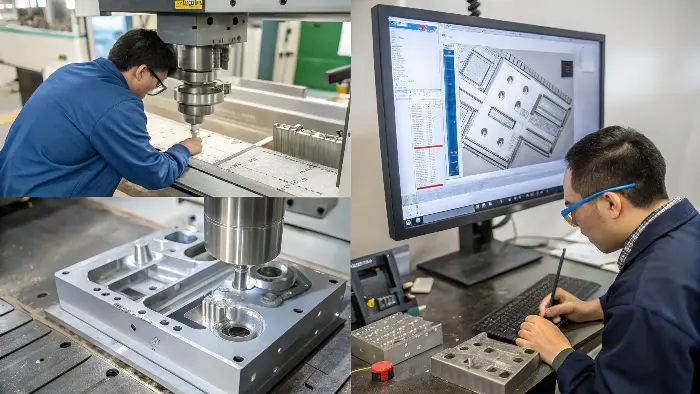

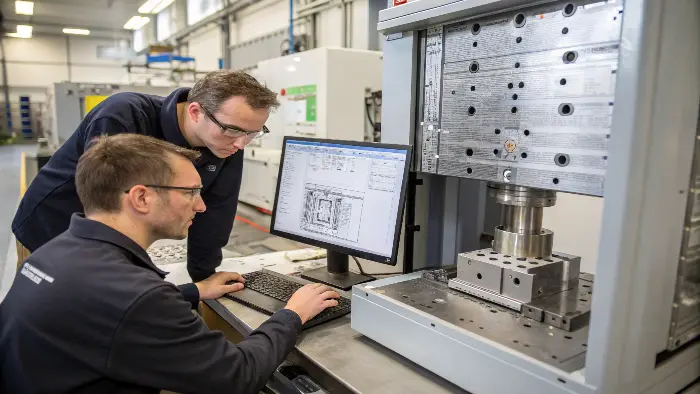

Once the part design is finalized, our engineers design the mold itself using specialized CAD software. This is a highly detailed 3D model of the entire mold assembly. It includes the core and cavity, the mold base, the cooling system designed for efficient heat removal, the ejector system to push the part out, and the runner and gate system that directs the flow of plastic into the cavity.

Step 3: Machining and Fabrication

With the mold design approved, we order the steel and begin machining. We use high-speed CNC machines to create the primary shapes of the core and cavity. For fine details, sharp corners, or special textures, we use EDM. Every component, from the main blocks to the smallest pins, is fabricated to tight tolerances.

Step 4: Assembly and Fitting

This is where craftsmanship really shines. Our experienced toolmakers take all the machined components and assemble them by hand. They ensure every part fits together perfectly. The two halves of the mold must align with extreme precision to prevent flash (thin excess plastic) on the final parts. I’ve seen our team spend hours meticulously fitting components to get it just right.

Step 5: Polishing and Texturing

The surface finish of your part is determined by the surface of the mold cavity. For a glossy part, the mold is polished to a mirror finish. This is often a delicate, manual process. If your part requires a specific texture, like a matte or grained finish, we apply it to the mold surface using chemical etching or laser texturing.

Step 6: Mold Trial and Validation (T1)

The moment of truth. We install the finished mold into an injection molding machine for its first trial run, known as T1. We inject plastic and produce the first sample parts. We carefully inspect these T1 samples for dimensional accuracy, appearance, and any defects. We send these samples to you for approval. If any adjustments are needed, we make them and run another trial until the mold is perfect.

How are plastic model molds made?

Your product has very fine details, sharp corners, or a complex surface texture. A standard mold-making approach might not capture these features correctly, leading to a final product that looks cheap or unfinished. Let’s explore the specialized techniques we use for high-precision molds, ensuring every detail of your design is perfectly replicated.

Molds for detailed plastic models demand extreme precision. This involves using high-speed CNC machining with very small cutting tools and advanced Wire EDM for sharp internal corners. The polishing process is often done by hand under a microscope. The design phase is also more critical, focusing on complex gating and venting to ensure plastic fills every tiny feature without any defects.

The Challenge of High Detail

When we talk about "model" molds, we’re talking about any mold that needs to produce parts with a high degree of detail. This could be for consumer electronics with tiny snap-fits, medical devices with micro-features, or actual scale model kits. The main challenges are ensuring the plastic can flow into these tiny spaces and that the part can be removed from the mold without breaking the delicate features. This requires a higher level of planning and execution.

Advanced Machining for Intricate Features

To create these details, we push our technology to its limits.

- 5-Axis CNC Machining: While standard 3-axis CNC is great for many parts, 5-axis machining allows the cutting tool to approach the workpiece from any angle. This lets us create complex curves and angled features in a single setup, which increases accuracy.

- Wire and Sinker EDM: EDM is absolutely essential for high-detail molds. Wire EDM uses a thin, electrically charged wire to cut through steel like a cheesewire, creating extremely sharp internal corners that are impossible to mill. Sinker EDM uses a custom-shaped electrode to burn a specific shape into the steel, perfect for creating logos, text, or complex textures.

Material and Gating Considerations

The choice of plastic resin is very important for detailed parts. Some plastics flow more easily into thin sections than others. We have to design the mold with the specific material in mind. The gating strategy is also critical. The gate is where plastic enters the cavity, and its location can affect how the part fills and what it looks like cosmetically. For a model part, we might use a very small "pin gate" or a "submarine gate" that breaks off cleanly, leaving almost no mark on the finished part.

I remember a project for a client making miniature housings for an audio device. The design had tiny, delicate snap-fits and a textured surface. We used a combination of high-speed milling with a 0.5mm tool and sinker EDM to get the detail just right. The first T1 samples were perfect, and the client was able to launch their product ahead of schedule. It’s projects like these that make our work so rewarding.

How are plastic shapes manufactured?

You have a finished, tested mold, but how does it actually create thousands of identical parts? Misunderstanding this production process can lead to issues like warping or incomplete parts, even with a perfect mold. Let’s walk through the injection molding cycle, the amazing process that brings your plastic shapes to life.

Plastic shapes are made using a process called injection molding. It involves clamping the two halves of the mold together tightly, injecting molten plastic resin under high pressure into the mold cavity, and then cooling the mold to solidify the plastic. Finally, the mold opens, and the finished part is pushed out by ejector pins.

The Injection Molding Cycle: A Step-by-Step Breakdown

The mold is just one half of the equation; the other is the injection molding machine. This machine performs a rapid, repeatable cycle to produce parts. Once we have perfected your mold, this is the process it will go through, sometimes hundreds of thousands of times.

The Injection Molding Cycle

The process is a loop that consists of a few key steps. The speed of this cycle determines how many parts you can make per hour.

- Clamping: The injection molding machine pushes the two halves of the mold together with immense force. This ensures the mold stays sealed shut against the pressure of the injected plastic.

- Injection: Plastic pellets are fed from a hopper into a heated barrel, where a screw melts and mixes them. The screw then pushes forward like a plunger, forcing the molten plastic into the mold cavity at high speed and pressure.

- Holding (or Dwelling): After the cavity is filled, pressure is maintained for a short period. This packs more material into the cavity to compensate for shrinkage as the plastic cools, ensuring the part is fully formed.

- Cooling: This is often the longest part of the cycle. Water or oil circulates through the cooling channels we designed into the mold. This removes heat from the plastic, causing it to solidify into its final shape.

- Mold Opening: The clamping unit retracts, opening the two halves of the mold.

- Ejection: The ejector pins in the mold push forward, pushing the finished, solid part out of the cavity. The part then falls into a collection bin, and the cycle is ready to begin again.

This entire cycle can take anywhere from a few seconds to over a minute, depending on the part’s size, thickness, and material. During the mold trial phase, we work to optimize these parameters—pressure, temperature, and time—to produce the best possible part in the shortest possible cycle time. This ensures you get high-quality parts efficiently and cost-effectively.

Conclusion

Manufacturing a plastic mold is a precise, multi-stage process that blends advanced technology with expert craftsmanship. Understanding this journey, from the initial DFM analysis to the final injection molding cycle, empowers you to make better decisions. It ensures you achieve high-quality, consistent results for your products and find the right manufacturing partner.