How We Eliminated Black Specks in High-Gloss Automotive Components?

Dealing with black specks on high-gloss parts is incredibly frustrating. You want a perfect finish, but these tiny imperfections force you to scrap parts, causing

Dealing with black specks on high-gloss parts is incredibly frustrating. You want a perfect finish, but these tiny imperfections force you to scrap parts, causing

Are you tired of seeing beautifully designed plastic parts ruined by ugly scratches and scuffs? These defects lead to high rejection rates, wasted materials, and

Are you struggling with parts that look strong but fail unexpectedly at a specific seam? This weakness, often found in fiber-reinforced plastics, can derail entire

Designing miniature plastic parts presents unique challenges. Weld lines, often a minor cosmetic flaw in larger components, can become critical structural weak points in micro-molded

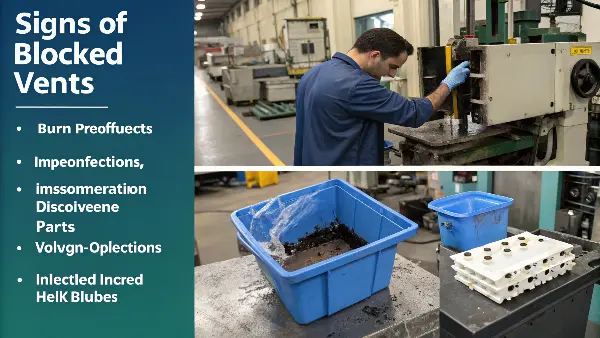

Struggling with unexplained defects like burn marks or short shots in your injection molded parts? These issues often point to a clogged venting system, a

Are you tired of dealing with injection molding defects like burn marks and short shots? These issues can ruin part quality and drive up production

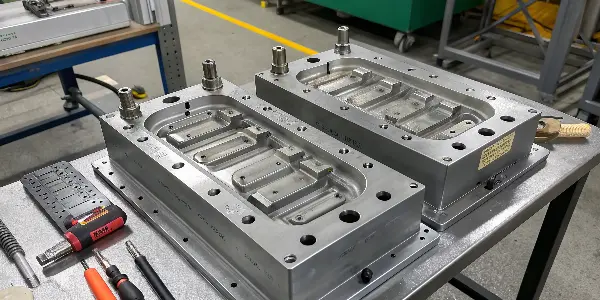

Struggling with inconsistent part quality? Flaws like sink marks, weld lines, and warping can derail your project, causing costly delays and rework. This often points

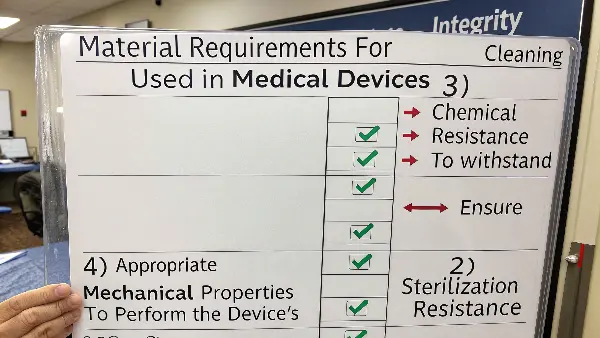

Struggling with the complexities of medical-grade plastics? A minor oversight in processing temperature can compromise an entire production run, leading to costly failures and regulatory

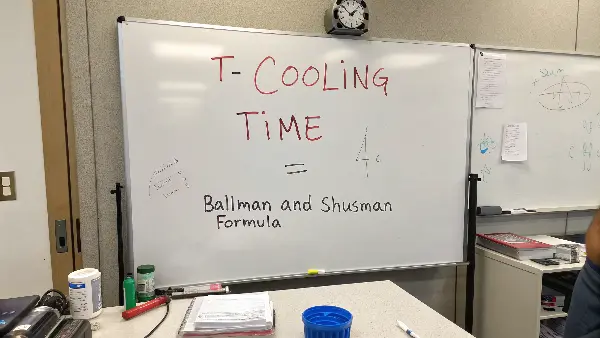

Struggling to balance speed and quality in your injection molding projects? Incorrect settings can lead to costly defects and delays, putting your entire production schedule

Struggling with color mismatches that damage your brand’s reputation and lead to costly production runs? These inconsistencies can frustrate customers and erode trust. Implementing a

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”