Struggling with post-production defects like sink marks and warpage? These issues waste time, increase costs, and delay your projects. Optimizing your part design from the very beginning is the most effective way to ensure a smooth, high-quality manufacturing run and avoid these costly headaches.

To prevent injection molding defects, focus on design optimization. Key strategies include ensuring uniform wall thickness, adding appropriate draft angles, and correctly placing gates and runners. These core design principles help control material flow, cooling rates, and pressure, which directly prevents common issues like sink marks, warping, and short shots. They form the foundation for a manufacturable and high-quality final product.

It’s a scenario I’ve seen countless times in my career as a mold engineer. A project manager like Alex comes to us with a design that looks great on paper but is a nightmare for manufacturing. The good news is that a few key adjustments at the design stage can make all the difference. Understanding the common pitfalls is the first step toward avoiding them completely. So, let’s break down what can go wrong and, more importantly, how to get it right from the start.

What Are the Most Common Defects in Plastic Injection Molding?

You’ve just received a batch of parts, but they’re full of cosmetic flaws or don’t fit together properly. Now you’re facing rework, delays, and frustrated clients. Understanding these common defects is the first step to identifying their root causes and preventing them in your next project, saving valuable time and money.

The most common defects in plastic injection molding include sink marks, warping, short shots, flash, and weld lines. These issues stem from improper material flow, uneven cooling, or incorrect pressure during the molding process. Each defect points to a specific problem area that can often be traced back to the initial part design or the mold’s construction.

In my experience, almost every defect can tell you a story about what happened inside the mold. As a project manager, being able to "read" these defects gives you a massive advantage. It helps you have more productive conversations with your manufacturing partner. Let’s look at the most frequent culprits I see.

Unpacking the Top 5 Molding Defects

Recognizing these issues early is key. When we receive a part design for a quote, these are the potential problems our engineers look for immediately.

| Defect Type | Description & Common Cause |

|---|---|

| Sink Marks | Small depressions on the surface. These almost always happen in thicker sections of a part where the plastic shrinks more as it cools. The root cause is usually non-uniform wall thickness. |

| Warping | The part bends or twists out of its intended shape after cooling. This is another result of differential shrinkage. If one area of the part cools and shrinks much faster than another, it creates internal stress that pulls the part out of shape. |

| Short Shot | The mold cavity isn’t completely filled, resulting in an incomplete part. This can be caused by trapped air, narrow flow paths in the design, or insufficient injection pressure. |

| Flash | A thin layer of excess plastic that seeps out of the mold cavity, typically at the parting line. It’s a sign that the two halves of the mold didn’t seal perfectly, often due to high pressure or a poorly designed parting line. |

| Weld Lines | A visible line where two or more fronts of molten plastic met as they flowed through the cavity. While sometimes just a cosmetic issue, they can also be a weak point in the part. |

Understanding this list is like having a diagnostic checklist. When you see a sink mark, you can immediately ask your team, "Can we thin out this wall section or core it out?" This proactive approach, starting from the design, is what separates a smooth project from a difficult one.

What Are the Key Design Considerations to Prevent These Defects?

You’ve identified the common defects, but now you feel stuck on how to actively prevent them from happening in the first place. You need clear, actionable design rules to follow. Ignoring these fundamentals can lock you into a cycle of costly tooling modifications and production delays down the road.

Three key design considerations are uniform wall thickness, proper draft angles, and well-placed radii. Maintaining consistent walls prevents sinks and warps. Draft angles ensure easy part ejection without damage. Radii, or rounded corners, reduce stress concentrations and improve material flow, which helps prevent cracks and short shots. Mastering these three areas is fundamental to successful part design.

When I review a new design, these three elements are the very first things I check. It’s like being a home inspector checking the foundation. If these core principles aren’t right, it doesn’t matter how fancy the rest of the design is; you’re going to have problems. A little extra time spent here saves weeks of headaches later. Think of it as building manufacturability right into the DNA of your product.

The Foundation of Good Part Design

Let’s dig into why these three rules are non-negotiable for anyone serious about quality. Getting them right from the start is the most impactful thing a project manager can do to ensure success.

Wall Thickness: The Golden Rule

The single most important rule in injection molding design is to maintain a uniform wall thickness. When you have a thick section connected to a thin section, the thick area cools much slower. As it cools, it shrinks and pulls material from the still-molten center, causing a sink mark on the surface. To avoid this, we recommend:

- Design for the thinnest possible wall that still meets your structural requirements.

- Use ribs and gussets to add strength instead of making the entire wall thicker.

- If thickness variations are unavoidable, make the transition gradual rather than abrupt. A smooth, tapered change helps the plastic flow and cool more evenly.

Draft Angles: The Secret to a Clean Release

A draft angle is a slight taper applied to the vertical walls of a part. Without it, the part would be nearly impossible to eject from the mold without scrape marks, breakage, or damage to the expensive mold itself.

- A general rule is 1-2 degrees of draft for most parts.

- Textured surfaces require more draft, sometimes up to 5 degrees or more, because the texture creates more friction.

- Always apply draft in the direction of the mold pull. It’s a simple change in CAD that makes a world of difference in production.

Radii: Eliminating Stress Hotspots

Sharp internal corners are a major source of stress in a plastic part. They can lead to cracks during ejection, assembly, or use. They also disrupt the flow of molten plastic.

- Add generous radii to all inside and outside corners. A good rule of thumb is to have an inside radius of at least 0.5 times the wall thickness.

_ This simple addition strengthens the part and significantly improves the flow of plastic into the mold, helping to prevent short shots and weld lines.

How Does Design Optimization Actually Work in Practice?

Knowing the design rules is one thing, but how do you apply them effectively in a real-world project with tight deadlines? It can feel overwhelming to balance functional needs with manufacturing constraints. Rushing this stage often leads to overlooking critical details that cause defects later.

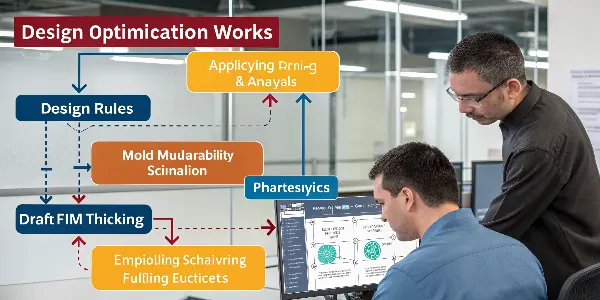

Design optimization works by using tools like Design for Manufacturability (DFM) analysis and Mold Flow simulation. DFM is a systematic review where manufacturing experts check for features like undercuts, wall thickness, and draft. Mold Flow software simulates how plastic will fill, cool, and warp, allowing you to digitally fix problems before any steel is cut.

When a client sends us a 3D model, the first thing we do isn’t to start building the mold. We run it through our optimization process. I think of this as a "pre-flight check." We use our experience and software tools to spot turbulence before the project ever takes off. I’ve personally seen Mold Flow analysis save clients tens of thousands of dollars by identifying a critical flaw that would have required a complete mold rebuild. It’s an essential step.

The Two Pillars of Modern Design Optimization

To make this process tangible, let’s break down the two most powerful tools we use at CAVITYMOLD to help project managers like Alex optimize their designs for flawless production.

Pillar 1: Design for Manufacturability (DFM)

A DFM review is a collaborative process. Our engineers sit down with your design and essentially put on "manufacturing glasses." We aren’t just looking at the part’s function; we’re looking at how we can make it efficiently and reliably, thousands of times over.

Here’s what our DFM report typically covers:

- Wall Thickness Analysis: We use software to color-code your part, instantly highlighting areas that are too thick or too thin.

- Draft Analysis: We check every vertical face to ensure it has adequate draft for clean ejection.

- Undercut Analysis: We identify any features that would get "stuck" in a simple open-and-close mold. This helps determine if more complex and costly mechanisms like side-actions or lifters are truly necessary.

- Parting Line Suggestion: We propose the most logical and cost-effective place to split the mold, which impacts tooling cost and the final appearance of the part.

Pillar 2: Mold Flow Simulation

If DFM is the expert visual inspection, Mold Flow is the x-ray. This powerful software allows us to simulate the entire injection molding process digitally. We can see:

- Fill Pattern: How the plastic flows into the cavity, helping us predict where weld lines and air traps might occur.

- Pressure and Temperature: We can check if injection pressures are too high or if there are hot spots that could cause degradation or cosmetic issues.

- Cooling Analysis: We can see how the part cools and predict exactly where and how much it will warp.

This data allows us to make precise, evidence-based recommendations. We can say, "If we move the gate from this location to that location, we can eliminate this weld line and reduce warpage by 30%." It turns guesswork into engineering.

Why is Gate and Runner Design So Critical for Defect Prevention?

You’ve perfected wall thickness and draft, but your parts are still showing flow lines or are not filling completely. It’s easy to overlook, but the system that delivers plastic to your part—the runner and gate—is just as important as the part design itself. A poor delivery system can ruin a perfectly designed part.

Gate and runner design is critical because it controls the speed, pressure, and direction of molten plastic flow into the mold cavity. The gate’s location determines where weld lines form and how stresses are distributed. The runner’s size affects fill time and material waste. Proper design ensures a balanced, complete fill, preventing defects like short shots and cosmetic flaws.

I often tell clients to think of the runner and gate system as the plumbing for the mold. If the pipes are too narrow, clogged, or enter the room from the wrong wall, you’ll have problems. Deciding on the right gate type and location is one of the most important decisions we make during the mold design phase. It directly influences part quality, cycle time, and even the type of cosmetic finish you can achieve on the final product.

Mastering the Art of Material Delivery

A well-designed runner and gate system isn’t just about getting plastic from point A to point B. It’s about doing it with precision and control. Let’s examine the key elements we consider to ensure your parts are a success.

The Role of the Runner

The runner is the channel cut into the mold that carries molten plastic from the sprue (the main entry point) to the gates. The goal is to design a runner that minimizes pressure drop and cools at the right rate.

- Full-Round Runners: These are the most efficient because they have the smallest surface-area-to-volume ratio, which reduces heat loss and pressure drop. However, they must be cut into both halves of the mold, which can increase tooling cost.

- Trapezoidal Runners: This is the most common and practical shape. It’s a good compromise between efficiency and ease of manufacturing, as it only needs to be cut into one side of the mold.

- Runner Balancing: In a multi-cavity mold, it’s crucial that all cavities fill at the same time and pressure. We achieve this by designing a "balanced" runner layout, ensuring the distance and path to each cavity are identical.

Choosing the Right Gate

The gate is the small opening where the plastic enters the part cavity itself. Its type and location are critical. It leaves a mark on the part, so its placement must be carefully considered for both function and aesthetics.

| Gate Type | When to Use It | Key Advantage |

|---|---|---|

| Edge Gate | The most common type, located on the parting line of the part’s edge. | Simple, low-cost, and easy to manufacture and de-gate (trim). |

| Submarine (Tunnel) Gate | Enters the part below the parting line and is sheared off automatically when the part is ejected. | Automates the de-gating process, reducing labor costs and cycle time. |

| Hot Tip Gate | Used with a hot runner system, injecting plastic directly into the part surface (often on the top). | Eliminates the runner, saving material waste and allowing for precise flow control. Leaves only a tiny mark. |

The gate location is arguably the most important decision. We place it to fill the part from the thickest section to the thinnest, pushing air out towards the vents. This simple principle helps prevent air traps, voids, and short shots, ensuring a solid, high-quality component every time.

Conclusion

Preventing injection molding defects begins long before production. By focusing on design optimization—uniform walls, proper draft, and smart gate placement—you can eliminate most common issues. This proactive approach, supported by DFM and Mold Flow analysis, ensures a smoother, more cost-effective manufacturing process from start to finish.