Designing strong plastic parts with features like ribs and bosses often leads to ugly sink marks on the surface. These cosmetic flaws can cause part rejections and project delays, frustrating both you and your client. But you can follow specific design rules to get structural integrity and flawless surfaces.

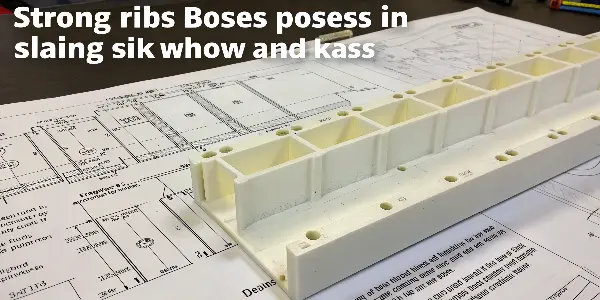

To engineer strong ribs and bosses without sink marks, you must follow strict design rules. The key is controlling the thickness of these features relative to the main wall. A rib’s thickness should be 40-60% of the nominal wall thickness. Also, use generous radii and draft angles to improve material flow and reduce stress, which are the main culprits behind these defects.

I remember a project with a client developing a new handheld device. They needed it to be tough, but the initial design was riddled with sink marks over every single rib. It looked terrible and failed drop tests. We had to go back to the drawing board, focusing on the fundamentals. These core principles of rib and boss design separate a well-engineered part from a problematic one. Let’s break down exactly how you can achieve that perfect balance of strength and aesthetics in your own projects.

How Can You Master Rib Design for Maximum Strength?

You add ribs to your part for stiffness, but they don’t seem to provide the strength you expected. This weakness can lead to field failures and damage your product’s reputation. Let’s explore the proven design rules that will guarantee your ribs provide maximum reinforcement.

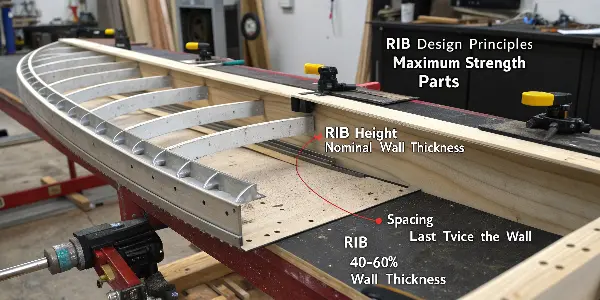

To master rib design for strength, focus on proper sizing and placement. Rib height should be no more than three times the nominal wall thickness. Their thickness should be between 40-60% of the wall. Also, space them apart by at least twice the wall thickness. Using multiple, smaller ribs is always better than one large, thick rib for achieving stiffness without defects.

When we talk about adding ribs, we’re really talking about increasing the part’s stiffness without adding a lot of material or thickness. Getting this right is a balancing act. If you make a rib too big, you get sink marks. If it’s too small, it provides no real benefit. The key lies in following a few golden rules that we at CavityMold have tested over thousands of projects. It all starts with the relationship between the rib and the wall it’s attached to. This relationship governs everything from structural performance to cosmetic appearance.

The "Golden Ratios" of Rib Design

The most important rule is the rib-to-wall thickness ratio. We always advise keeping the rib thickness between 40% and 60% of the nominal wall thickness. For example, if your part wall is 3mm thick, your rib should be no more than 1.8mm thick. This ratio is critical because it helps manage how the plastic cools. Plastic shrinks as it cools, and thicker sections cool slower than thinner ones. If a rib is too thick, it will cool much slower than the wall, pulling material inward and creating a sink mark on the opposite surface. Sticking to the 40-60% rule helps ensure the cooling rates are similar, which minimizes this risk dramatically.

| Parameter | Recommended Guideline | Why It’s Important |

|---|---|---|

| Rib Thickness | 40% – 60% of Wall Thickness | Prevents sink marks by managing cooling rates. |

| Rib Height | ≤ 3x Wall Thickness | Prevents mold filling issues and high stress. |

| Rib Spacing | ≥ 2x Wall Thickness | Ensures uniform cooling and prevents weak spots. |

| Base Radius | ≥ 25% of Wall Thickness | Reduces stress concentration and cracks. |

| Draft Angle | 0.5° – 1.5° per side | Helps the part eject easily from the mold. |

Height and Spacing Considerations

Beyond thickness, the height and spacing of your ribs are just as important. A common mistake is to design one massive rib, thinking it will add the most strength. In reality, a series of shorter, well-spaced ribs provides far better stiffness and avoids molding defects. As a rule of thumb, rib height should not exceed three times the nominal wall thickness. Taller ribs can be difficult to fill with plastic during injection and can lead to trapped air or weak points. Also, spacing between ribs should be at least two times the nominal wall thickness. This gives the material enough space to cool uniformly and prevents thin sections of the tool from overheating or breaking. Following these guidelines gives you a rigid part that is also easy to manufacture.

What’s the Secret to Designing Bosses Without Sink Marks?

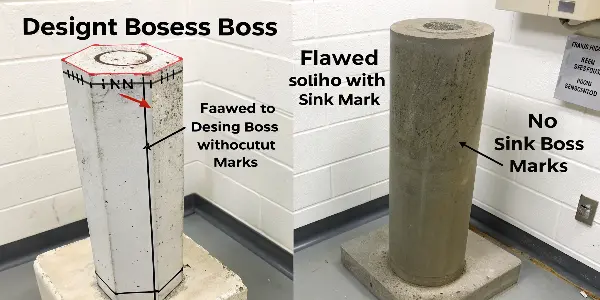

You need screw bosses for assembly, but they keep creating noticeable sink marks on the show surface. These cosmetic flaws can ruin your product’s appearance and lead to costly rework. The secret is to design them as cored-out, standalone features, not as solid pillars.

The secret to designing bosses without sink marks is to avoid thick, solid sections of plastic. Make the boss wall thickness 40-60% of the nominal part wall. Core out the center to maintain a uniform thickness. You should also detach the boss from nearby walls or connect it with thin ribs. This prevents localized heat buildup, which is the direct cause of sink marks.

Bosses are essential for assembling plastic parts, but they are also one of the most common causes of cosmetic defects. A project manager I worked with, Alex, was developing a casing for a consumer electronic device. The design had several bosses placed directly against the outer wall, and every single one created a sink mark. The product looked cheap and poorly made. We solved this not by making the bosses smaller but by changing their fundamental design. The goal is to create a strong anchor point for a screw without creating a large mass of plastic that will shrink and pull on the surface.

Core-Out Your Bosses for Uniformity

A solid boss is a sink mark waiting to happen. The best practice is to always core out your bosses. This means designing them like hollow cylinders instead of solid posts. Just like with ribs, the wall thickness of the boss should be kept to around 60% of the main part wall. This ensures the boss and the main wall cool at a similar rate, preventing warping and sinking. The hole in the center should be designed to accommodate your screw or insert, but the surrounding wall should remain thin and uniform. This simple change is the most effective way to eliminate sink marks caused by bosses. It also has the added benefit of reducing material usage and shortening the cycle time, which saves money.

Isolate Bosses from Main Walls

Another common design error is placing a boss directly at the intersection of two walls or right against a vertical wall. This creates a very thick section of plastic where the boss and wall meet, which is guaranteed to cause a sink mark. The solution is to isolate the boss. Move it away from the wall and connect it with thin support ribs if needed. These connecting ribs should also follow the 40-60% thickness rule. This strategy breaks up the large mass of plastic into smaller, more manageable sections that can cool uniformly. You can also add gussets at the base of the boss for extra support. Gussets are small, triangular ribs that strengthen the boss without adding significant thickness, making them a great tool for achieving both strength and a flawless finish.

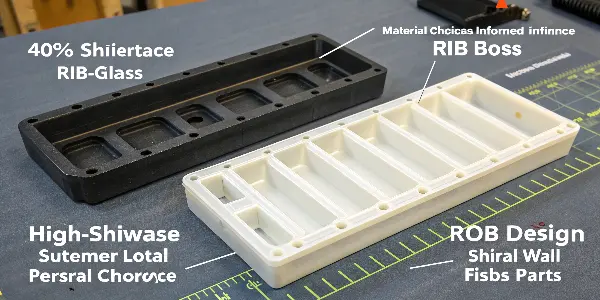

How Do Material Choices Influence Rib and Boss Design?

You’ve followed all the design rules for ribs and bosses, but you’re still getting defects. The problem might not be your design but your material choice. Different plastics shrink and flow differently, directly impacting your results.

Material choice is critical because each plastic has a unique shrinkage rate. High-shrinkage materials like polypropylene require thinner ribs (closer to 40% of wall thickness) to avoid sink marks. In contrast, low-shrinkage materials with fillers, like glass-filled nylon, can tolerate slightly thicker ribs (up to 60%). You must consult the material datasheet and adjust your design rules accordingly for a successful outcome.

I once had a client who was switching from ABS to Polypropylene for a product to save on costs. They kept the exact same part design, which was optimized for ABS. When we molded the first samples in Polypropylene, the parts came out with deep sink marks over every rib and boss. The design itself was fine, but it wasn’t right for the new material. This taught me a valuable lesson: design rules are not one-size-fits-all. They have to be adapted based on the specific behavior of the plastic you are using. Every material tells a different story during the molding process.

Understanding Shrinkage Rates

Every plastic shrinks as it cools from a molten to a solid state. The rate of this shrinkage is one of the most important properties to consider. Materials are generally categorized into two groups: amorphous and semi-crystalline.

- Amorphous plastics (like ABS and Polycarbonate) have a lower, more uniform shrinkage rate. They are more forgiving, and you can sometimes get away with slightly thicker ribs without severe sink marks.

- Semi-crystalline plastics (like Nylon, Polypropylene, and Acetal) have a much higher and less uniform shrinkage rate. These materials are very prone to sinking and warping. When designing with these plastics, you must be very strict with the 40-60% rule, often staying closer to the 40% side.

Below is a table showing typical shrinkage rates for common materials and how that affects rib design.

| Material Type | Examples | Shrinkage Rate | Rib Thickness Guideline |

|---|---|---|---|

| Amorphous | ABS, PC, PS | Low (0.5-0.7%) | Can use up to 60% of wall thickness. |

| Semi-Crystalline | PP, PE, Nylon | High (1-3%) | Should stick closer to 40% of wall thickness. |

| Filled Materials | Glass-Filled Nylon | Very Low (<0.5%) | Less prone to sink, can sometimes exceed 60%. |

The Role of Fillers

Adding fillers like glass fibers or mineral powders to a plastic can drastically change its properties. One of the biggest changes is a reduction in the shrinkage rate. Glass-filled nylon, for example, shrinks much less than unfilled nylon. This makes it less prone to sink marks, which means you might be able to design slightly thicker ribs and bosses for extra strength without negative cosmetic effects. However, fillers also affect how the plastic flows into the mold. The fibers can align in a certain direction, which can cause the part to warp in unexpected ways. This is why it’s so important to run a mold flow analysis, especially when working with filled materials. An analysis can predict these issues and help you adjust the design before cutting steel.

Are There Advanced Techniques to Avoid Common Design Flaws?

Even with perfect classic design rules, sometimes you face challenges that require more advanced solutions. You might need extra strength in a specific area or need to eliminate a stubborn defect. This is where creative engineering techniques come into play.

Yes, there are advanced techniques. Using gussets at the base of ribs and bosses adds significant strength without adding thickness that causes sink marks. Designing with coring and cutouts removes unnecessary material from thick sections. Another technique is to use a "show" surface and a "functional" surface, hiding any unavoidable sink marks on the non-visible side of the part.

Going beyond the basic rules can really elevate your part design. Think of the standard guidelines as your foundation. But for complex parts, you need a few more tools in your toolbox. One of my favorite examples is from a project involving a large housing for an industrial machine. The housing needed to be incredibly rigid, but the client did not want to see any cosmetic flaws on the exterior. We couldn’t just add big ribs everywhere. Instead, we used a smart combination of gussets, coring, and a well-planned texture on the outside surface to achieve both the strength and the look they wanted.

Strategic Use of Gussets and Coring

Gussets are small, triangular support features that are incredibly effective at reinforcing ribs and bosses. You can place them at the base of a boss to prevent it from breaking off under load. You can also use them to connect a rib to a wall for extra stiffness. The beauty of a gusset is that it adds strength without creating a thick mass of plastic. They should still follow the 40-60% thickness rule, but their shape distributes stress very efficiently.

Coring is another powerful technique. It simply means removing plastic from areas where it isn’t needed for structural purposes. If you have a thick section on your part that is causing a sink mark, ask yourself if all that material is truly necessary. Often, you can "core out" the back of that section, creating a more uniform wall thickness without compromising the part’s function. This is particularly useful for parts with complex geometries.

Hiding Blemishes and Using Texture

Sometimes, a minor sink mark is simply unavoidable due to the part’s design constraints. In these cases, you can use a clever trick: design the part with a clear "A" side and "B" side. The "A" side is the cosmetic or "show" surface that the customer will see. The "B" side is the functional, hidden side. You can design your ribs and bosses on the "B" side, so if any minor sink mark does appear, it’s on a surface that is never seen. This is a very common and practical solution.

Furthermore, applying a texture to the cosmetic surface can be a great way to hide minor imperfections. A light texture, like a matte or sandblasted finish, is very effective at masking small sink marks or variations in gloss. It scatters light, making it much harder for the human eye to pick up on slight depressions in the surface. This can turn a part that might have been rejected into a perfectly acceptable, high-quality product.

Conclusion

Mastering rib and boss design is about balancing strength with aesthetics. By following the core rules—like the 40-60% thickness ratio—and adapting them to your specific material, you can avoid sink marks. Advanced techniques like gussets and coring provide even more control for creating flawless, functional parts.