Struggling with inconsistent part quality? Flaws like sink marks, weld lines, and warping can derail your project, causing costly delays and rework. This often points to one critical, yet overlooked, factor in the molding process: precise temperature control. Without it, achieving perfection is nearly impossible.

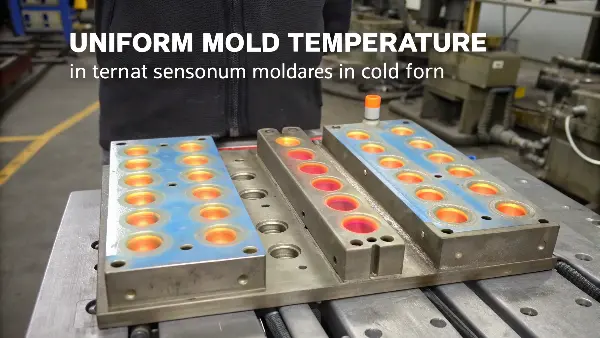

The key to superior surface finish and dimensional stability lies in maintaining a highly uniform and consistent temperature across the entire mold surface. We achieve this through advanced cooling channel design, state-of-the-art thermal analysis, and techniques like conformal cooling, ensuring every part meets exact specifications cycle after cycle.

When you hand over a design, you expect the final parts to match it perfectly. But often, what comes out of the mold is a frustrating mix of good and bad parts. This inconsistency can be a nightmare for project managers like you. You need a partner who understands that the secret isn’t just in the steel, but in the heat management within it. At CAVITYMOLD, we’ve spent over a decade mastering this, and it’s time we showed you how we turn thermal challenges into your competitive advantage. Keep reading, and I’ll break down the exact strategies we use to deliver flawless results.

Why Is Uniform Mold Temperature the Secret to Flawless Parts?

Ever received a batch of parts where some are perfect, but others are slightly off? This inconsistency can be a huge headache, leading to failed assemblies and unhappy clients. The root cause is almost always uneven temperature distribution across the mold, a problem that sabotages quality from the inside out.

A uniform mold temperature ensures that the molten plastic cools at the same rate everywhere. This prevents internal stresses, which cause warping, and allows the plastic to fill the cavity evenly, which eliminates surface defects. It’s the foundation for producing identical, high-quality parts in every single cycle.

So, how does a simple thing like temperature have such a huge impact? Think about what happens when you pour molten plastic into the mold. It flows like a river, and the mold walls are the riverbanks. If some parts of the bank are freezing cold and others are warm, the flow becomes chaotic. This is exactly what happens inside a poorly controlled mold. The plastic that touches colder spots solidifies too quickly, while the plastic in hotter areas stays molten longer. This creates a cascade of problems. I remember a project for a client in Australia who was making large electronic enclosures. They were struggling with terrible warping issues. Their previous supplier just couldn’t get it right. When we took over, our first step wasn’t to change the plastic or the machine; it was to analyze the mold’s thermal profile.

The Science of Even Cooling

Even cooling is all about controlling the phase change of plastic from a liquid to a solid. To achieve this, we focus on two core principles:

- Consistent Heat Removal: The goal is to pull heat out of the plastic part at the same rate across its entire surface.

- Targeted Temperature Zones: Different features of a part may require slightly different temperatures for optimal results.

The Consequences of Poor Temperature Control

When the temperature is not uniform, it directly impacts the final part in several negative ways. Below is a breakdown of the common problems we see and their direct link to temperature issues.

| Problem | How Poor Temperature Control Causes It | Our Solution |

|---|---|---|

| Warping | One area of the part cools and shrinks much faster than another, creating internal stress that bends the part after ejection. | We design cooling channels that closely follow the part’s geometry, ensuring all sections cool at a balanced rate. |

| Sink Marks | The surface of the part cools and hardens while the inside is still molten. As the inside cools and shrinks, it pulls the soft surface inward. | We ensure the mold surface temperature near thick sections is precisely managed to allow for proper packing pressure and solidification. |

| Weld Lines | When two plastic flows meet, if the mold is too cool, they don’t merge properly, creating a visible and weak line. | We maintain a higher, uniform mold temperature to keep the plastic flow fronts hot enough to fuse together perfectly when they meet. |

| Poor Surface Finish | A cold mold can cause the plastic to "freeze" the moment it touches the surface, failing to replicate the fine texture of the mold steel. | We precisely control the surface temperature to give the plastic enough time to perfectly copy every detail of the mold’s polished or textured surface. |

This systematic approach to thermal management is a core part of our philosophy at CAVITYMOLD. It’s how we ensure that a project manager like Alex in Australia gets predictable, high-quality results every time.

What Advanced Cooling Techniques Do We Use to Master Mold Temperature?

You know that generic, straight-drilled cooling channels often fail on complex parts. They create hot and cold spots that lead to defects. To deliver superior quality, you need a molder who thinks beyond the basics and uses technology to solve these thermal challenges before they even start.

At CAVITYMOLD, we primarily use Conformal Cooling alongside advanced thermal simulation. This involves creating cooling channels that follow the exact shape of the part’s cavity and core. This targeted approach removes heat uniformly, drastically reducing cycle times and eliminating quality issues like warping and sink marks.

The old way of drilling straight lines for cooling is like trying to cool a human body with a few straight pipes—it just doesn’t work well. Some areas will be too cold, and others, like the fingers and toes, will stay hot. For a mold, this means areas like ribs, bosses, and deep corners become thermal bottlenecks. That’s why we moved past these outdated methods years ago. Our approach is much more sophisticated and tailored to each specific project, ensuring every nook and cranny of the mold is at the perfect temperature.

A Deep Dive into Our Cooling Arsenal

To truly master mold temperature, we employ a range of techniques, often in combination. Our engineering team, led by designers with over a decade of experience, selects the best method based on the part’s geometry, material, and quality requirements.

-

Thermal Simulation and Mold Flow Analysis:

Before we cut any steel, our process begins with software. We run detailed mold flow and thermal simulations. This allows us to predict exactly where hot spots will occur. I often show this to clients on a video call. They can see a 3D heat map of their part inside the mold, with red spots highlighting potential problem areas. This visual evidence makes it clear why a standard cooling design won’t work and helps justify the use of more advanced techniques. -

Conformal Cooling:

This is our primary weapon against uneven temperature. Instead of straight lines, we design cooling channels that snake and curve, staying a consistent distance from the mold surface. This is like installing a custom radiator perfectly shaped for your part.- How it’s made: We often use a specialized metal 3D printing process (Direct Metal Laser Sintering – DMLS) to create mold inserts with these complex internal channels.

- The benefit: It can reduce cooling time by up to 50% and dramatically improve part quality. For a recent medical device component, conformal cooling was the only way to prevent sink marks on a thick boss feature.

-

Baffles and Bubblers:

These are clever solutions for cooling long, thin cores—the kind used to create holes or deep features in a part.- Baffles: A blade inside the cooling channel forces the coolant up one side and down the other, ensuring it reaches the tip of the core pin.

- Bubblers: A tube inside the channel shoots a "bubble" of coolant to the tip, which then cascades down the outer walls.

This combination of predictive analysis and advanced hardware is what sets us apart. We don’t just drill holes and hope for the best. We engineer a bespoke thermal management system for every mold we build.

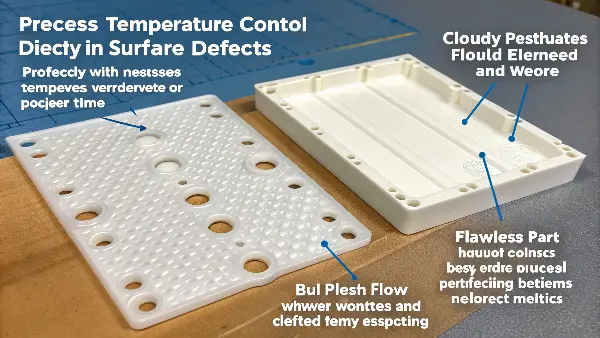

How Does Precise Temperature Control Directly Eliminate Surface Defects?

You’ve probably seen them: cloudy patches, visible flow lines, and dull spots on what should have been a perfectly glossy part. These surface defects are frustrating because they ruin the product’s aesthetic appeal and can sometimes indicate a structural weakness. They are often blamed on the material, but the real culprit is usually a lazy approach to mold temperature.

By precisely controlling the mold’s surface temperature, we ensure the plastic has enough time to perfectly replicate the mold’s texture before it solidifies. A warmer, uniform temperature prevents premature freezing of the polymer skin, eliminating flow marks, improving gloss, and ensuring weld lines are cosmetically invisible and strong.

I’ve met with so many project managers who feel stuck in a cycle of trial and error, constantly adjusting machine parameters to fix surface flaws. But it’s like adjusting the sails on a boat with a hole in it. The real problem is in the mold’s design. We believe in fixing the problem at its source. By engineering the mold’s thermal system correctly from day one, we make the molding process stable and repeatable, so you get the same beautiful finish on the first part and the millionth part.

Connecting Temperature to Common Surface Flaws

To understand how this works, let’s break down the most common surface defects and see how our temperature strategies solve them. Each defect tells a story about what happened to the plastic as it filled the cavity.

-

Weld Lines (or Knit Lines):

These form where two or more plastic flow fronts meet. If the mold is too cool, the fronts have already started to harden and can’t merge together seamlessly.- The Problem: This creates a visible line that is also a structural weak point.

- Our Solution: We run the mold at a slightly higher, very stable temperature. This ensures the flow fronts are still fully molten when they meet, allowing the polymer chains to entangle and create a strong, invisible bond. We use thermal simulation to predict where weld lines will occur and place cooling channels strategically to keep those areas warm.

-

Gloss and Texture Replication:

The final gloss of a part is a direct copy of the mold’s steel surface. If the plastic freezes the instant it touches the mold wall, it doesn’t have time to settle in and pick up the microscopic details of the polished surface.- The Problem: A dull, low-quality appearance, even with a highly polished mold.

- Our Solution: We often specify a higher mold surface temperature for high-gloss parts. This creates a momentary "hot skin" of molten plastic against the mold wall, giving it the crucial fraction of a second needed to perfectly replicate the surface. Conformal cooling is key here to maintain this higher temperature without dramatically increasing cycle time.

-

Flow Marks (or "Record Grooves"):

These are wavy patterns or streaks on the part surface that follow the path of the plastic flow.- The Problem: Creates an unacceptable cosmetic look, especially on large, flat surfaces.

- Our Solution: This is usually caused by a "stick-slip" effect where the plastic freezes and unfreezes as it flows over a cold mold surface. By raising the overall mold temperature and ensuring it’s uniform, we provide a smooth, consistent surface for the plastic to flow over, eliminating these marks entirely.

By treating the mold temperature as a primary design parameter, not an afterthought, we transform the molding process from a black box into a predictable science.

How Do We Prevent Part Warping and Shrinkage With Thermal Management?

There’s nothing more frustrating than designing a part to precise dimensions, only to have it come out of the mold twisted and warped. This issue, known as poor dimensional stability, can completely halt production, as parts won’t fit together in the final assembly. This is a direct result of uncontrolled shrinkage.

We prevent warping by engineering the mold’s cooling system to ensure the part cools and shrinks uniformly. By using thermal analysis and conformal cooling, we eliminate hot and cold spots, which prevents the internal stresses that cause parts to bend and twist after they are ejected from the mold.

All plastics shrink as they cool—it’s an unavoidable law of physics. The problem isn’t the shrinkage itself, but differential shrinkage. This happens when one part of the component shrinks much more or much faster than another. Imagine a part that is thick on one end and thin on the other. The thin end will cool and solidify rapidly, while the thick end remains hot and continues to shrink. This difference creates immense internal stress, and once the part is ejected from the constraint of the mold, that stress is released, causing it to warp.

Our Strategy for Dimensional Control

Our approach is to control the rate of shrinkage across the entire part. We manage the heat, so the part cools down as a single, cohesive unit. This is how we ensure the part that comes out of the mold matches your CAD file.

-

Targeted Cooling for Varying Thickness:

We pay special attention to areas with different wall thicknesses. Our thermal simulations pinpoint these areas, and we design the cooling layout accordingly.- Thick Sections: These areas hold more heat and need more aggressive cooling. We might place conformal cooling channels closer to the surface here or use materials with higher thermal conductivity for the mold inserts.

- Thin Sections: These can cool too quickly. We might actually need to keep these areas warmer to balance the cooling rate with the thicker sections.

-

The Role of Gate Location and Packing:

Temperature control works hand-in-hand with the injection process. The gate is where the plastic enters the mold. Its location is critical.- We position gates to ensure the cavity fills evenly and to allow for proper "packing." The packing phase is when we hold pressure after the mold is filled, forcing more plastic in to compensate for shrinkage as it cools.

- A properly cooled mold allows us to maintain this packing pressure effectively until the gate freezes off, locking the part into its correct dimensions.

A Practical Example: The Enclosure Lid

I recall a project for a large electronics housing. The lid was a large, flat part with reinforcing ribs on the inside. The client’s original parts were warping like a potato chip. Our analysis showed the flat areas were cooling much faster than the thick ribs.

| Our Diagnostic Steps | Our Implemented Solution | The Final Result |

|---|---|---|

| 1. Thermal Simulation: Our MoldFlow analysis created a heat map that clearly showed the ribs staying hot (red) long after the flat surface was cool (blue). | 1. Hybrid Cooling Design: We used high-efficiency baffling in the ribs to pull heat out quickly. | The new parts were dimensionally stable, flat, and fit the housing base perfectly. |

| 2. Shrinkage Analysis: The simulation predicted exactly how the part would twist based on the uneven cooling. | 2. Optimized Gate Location: We moved the gate to the center to promote a more even filling pattern and packing. | The cycle time was reduced by 20% because the cooling was now more efficient and balanced. |

| 3. Material Review: We confirmed the selected material (ABS) had a specific shrinkage rate that we needed to manage. | 3. Precise Temperature Control: We specified a precise water temperature and flow rate for each cooling circuit to execute the design. | The client was able to launch their product on schedule without any assembly issues. |

This complete, systematic approach is how we take the guesswork out of molding. We don’t just solve warping; we engineer it out of the process from the very beginning.

Conclusion

In short, mastering mold temperature is not just a technical detail; it is the core of our commitment to quality at CAVITYMOLD. By combining advanced simulation with techniques like conformal cooling, we deliver parts with flawless surfaces and precise dimensions, ensuring your project succeeds without costly delays or rework.