Nylon is a fantastic material, but it’s notoriously difficult to mold correctly. When the process isn’t perfect, parts can fail, leading to project delays, blown budgets, and a damaged reputation. We understand these challenges because we’ve spent years perfecting the solutions.

To optimize nylon injection molding, we focus on four critical areas. First, we ensure meticulous material drying to prevent moisture-induced degradation. Second, our mold designs incorporate strategic cooling, gating, and venting for dimensional stability. Third, we establish precise process parameters for temperature and pressure. Finally, we consider post-molding conditioning to guarantee long-term part performance and toughness.

Optimizing nylon injection molding is much more than just tweaking a few settings on a machine. It’s a comprehensive approach that begins long before the raw material even gets near the mold. It requires a deep understanding of the material’s unique chemistry and a commitment to precision at every single stage. Let’s break down how we tackle each critical step to ensure your parts perform exactly as you designed them, every single time.

Why is Proper Nylon Drying the First Step to Flawless Parts?

You selected nylon for its strength and durability, but your final parts are coming out brittle. This unexpected weakness can cause catastrophic failures in the field. It can ruin your product’s reputation and lead to costly recalls. The problem often starts with one simple, but absolutely critical, step: proper material drying.

Properly drying nylon is vital because moisture causes a chemical reaction called hydrolysis during molding, which breaks down the polymer chains. This severely reduces mechanical properties like strength and impact resistance. It can also cause visual defects on the part’s surface. We ensure nylon is precisely dried to the manufacturer’s specification, typically below 0.2% moisture content, using specialized equipment to prevent part failure and guarantee performance.

Nylon is a hygroscopic material. This just means it loves to absorb moisture from the surrounding air. While a little moisture is good for the final part’s toughness, too much moisture during the molding process is disastrous. When wet nylon pellets are heated to melting temperature inside the molding machine, the water molecules trigger hydrolysis. This reaction literally chops up the long, strong polymer chains that give nylon its strength. The result is a part that might look fine but is internally compromised and weak.

At CavityMOLD, we treat material handling as the foundation of a successful project.

The Right Equipment for the Job

We don’t use simple hot air ovens. They just heat the air, which is often humid itself, and can’t effectively remove the moisture bound inside the nylon pellets. Instead, we use dehumidifying or desiccant dryers. These systems use a special material called a desiccant to pull all the moisture out of the air before it’s used to dry the nylon. This ensures we achieve the target moisture level, which we verify with a moisture analyzer.

Finding the Sweet Spot

Drying isn’t just about heat; it’s about balance. Over-drying nylon can be almost as bad as under-drying. If you remove too much moisture or use a temperature that’s too high, you can start to degrade the material before it’s even molded. This can cause discoloration and reduced flow. We follow the material supplier’s data sheet to the letter, controlling both temperature and drying time precisely.

| Drying Condition | Material Property Impact | Resulting Part Quality |

|---|---|---|

| Under-Dried | Hydrolysis breaks polymer chains. | Brittle, weak, surface defects (splay). |

| Properly Dried | Polymer chains remain intact. | Strong, tough, dimensionally stable. |

| Over-Dried | Oxidation and thermal degradation. | Discolored, poor flow properties, potentially brittle. |

I remember a project for a client making automotive clips. Their previous supplier was having constant issues with the clips snapping during assembly. After analyzing their process, we found they were using a simple hot air dryer. By implementing our strict dehumidifying drying protocol, we eliminated the brittleness completely. The problem wasn’t the part design or the material choice; it was simply a failure to respect the first rule of nylon molding.

How Does Mold Design Directly Impact Nylon Part Quality?

Your team has designed the perfect component, the material is specified, but the molded parts are plagued with issues. You see ugly sink marks, parts are warping out of shape, and they don’t fit together correctly. These defects can derail your project, forcing costly mold modifications and pushing back your launch date. The source of these problems almost always points back to the design of the injection mold itself.

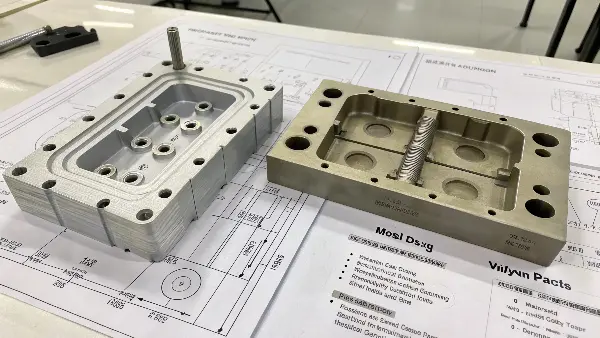

Mold design is critical for nylon because it directly controls how the molten plastic flows, cools, and solidifies. An optimized mold uses strategic cooling channels to manage shrinkage and warping, proper gate design and location to prevent weak weld lines, and effective venting to eliminate trapped gases. This careful design ensures part strength, dimensional stability, and a flawless cosmetic finish.

A mold is not just a hollow cavity. It is a complex piece of thermal management equipment. For a material like nylon, which has a relatively high and sharp melting point and is prone to shrinkage, the mold’s design is paramount. As your manufacturing partner, our engineering team focuses intensely on several key areas before any steel is cut. This collaborative approach with our clients, like Alex, ensures we get it right from the start.

The Importance of Cooling

Nylon’s shrinkage rate can be significant, and if it doesn’t cool uniformly, the part will warp. It’s that simple. We design cooling channels that follow the geometry of the part as closely as possible. We analyze the design to identify thick sections that will hold more heat and add extra cooling there to balance the thermal load. For very demanding applications, we might even suggest conformal cooling, where the cooling channels are 3D printed to perfectly match the part’s surface, providing the ultimate level of temperature control.

Smart Gating and Runner Systems

The gate is the entry point for the plastic into the mold cavity. Its location is a critical decision. A poorly placed gate can create weld lines—where two plastic flows meet—in a structurally sensitive area, creating a weak point. It can also cause "jetting," where the plastic shoots across the mold instead of filling smoothly. We use mold flow analysis software to simulate the filling process. This allows us to determine the ideal gate type and location to ensure smooth, uniform filling and place weld lines in non-critical areas, preserving the part’s integrity and appearance.

Letting the Air Out

When molten plastic rushes into the mold cavity, the air inside needs a way to escape. If it can’t get out fast enough, it gets compressed and superheated by the plastic, causing burn marks on the part. This trapped air can also prevent the mold from filling completely, resulting in "short shots." We design small but essential vents into the mold at the last points to fill. These vents are small enough to let air out but not so large that plastic can escape, ensuring a complete, defect-free part. This attention to detail in the mold design is how we build reliability into your product from the ground up.

What Are the Critical Injection Molding Parameters for Nylon?

You have a perfect mold from a great supplier and you’re carefully drying your material. Yet, you’re still getting inconsistent parts. Some batches are strong, others are brittle. Some are dimensionally stable, others are warped. This inconsistency is a project manager’s nightmare. It leads to high scrap rates and an unpredictable final product, eating directly into your bottom line. The solution lies in mastering the final piece of the puzzle: the injection molding process parameters.

The most critical injection molding parameters for nylon are melt temperature, mold temperature, injection pressure, and injection speed. A high mold temperature (around 70-90°C) is essential for developing proper crystallinity, which gives the part its strength and stability. Precise control over melt temperature and injection speed ensures the mold fills completely without degrading the material. Consistency in these parameters is key.

Running an injection molding machine is a science. You can’t just rely on old settings from a previous job. Every material, and even different grades of nylon, has its own unique processing window. At CavityMOLD, we don’t guess. We use a scientific molding approach to establish a robust and repeatable process. This means we systematically test the limits to find the optimal settings for your specific part and material combination.

Mold Temperature Defines Part Properties

For semi-crystalline materials like nylon, mold temperature is arguably the most important parameter. It controls the rate of cooling, which in turn controls the level of crystallinity in the final part.

- A hot mold (e.g., 80°C) allows the polymer chains to arrange themselves into an orderly, crystalline structure. This results in a part with higher tensile strength, better wear resistance, and greater dimensional stability. The trade-off is often a slightly longer cycle time.

- A cold mold "freezes" the material quickly, creating a more amorphous structure. This can make the part tougher and more flexible but can also lead to more post-mold shrinkage and lower long-term stability.

For most engineering applications, a hot mold is the correct choice, and we ensure our molds are designed to handle and maintain these temperatures uniformly.

Balancing Temperature, Pressure, and Speed

Melt temperature, injection speed, and pressure all work together. We need to heat the nylon enough so it flows easily (Melt Temperature), but not so much that it degrades. We need to inject it fast enough to fill the part before it freezes (Injection Speed), but not so fast that we shear and burn the material. Finally, we apply packing pressure after the mold is filled to compensate for shrinkage as the part cools (Packing Pressure).

Here are some typical starting points, though these are always optimized for the specific part geometry:

| Parameter | Typical Range (Glass-Filled PA66) | Impact on Part Quality |

|---|---|---|

| Melt Temperature | 275-300 °C (527-572 °F) | Affects viscosity and material degradation. |

| Mold Temperature | 80-95 °C (176-203 °F) | Controls crystallinity, shrinkage, and surface finish. |

| Injection Speed | Moderate to Fast | Influences filling pattern, weld lines, and shear heat. |

| Packing Pressure | 50-80% of Injection Pressure | Compensates for shrinkage, prevents sinks and voids. |

Finding the perfect balance of these variables is what separates an average molder from an expert. It’s this process control that ensures the first part we make is identical to the ten-thousandth, giving you the consistency and reliability you need.

Does Post-Molding Conditioning Matter for Nylon Parts?

Your nylon components have just come off the molding machine. They look perfect and pass all initial quality checks. But weeks later, either in storage or in the hands of your customer, they start to fail. They seem more brittle than expected, or maybe they’ve changed shape just enough to cause problems in an assembly. This delayed failure is frustrating and can seriously damage trust in your product. The problem isn’t the molding; it’s what happens after molding.

Yes, post-molding conditioning is frequently essential for nylon parts. When nylon is molded, it is in a dry, brittle state. Conditioning is a controlled process of re-introducing moisture into the part. This allows the nylon to regain its natural toughness, ductility, and impact strength. It also ensures the part is dimensionally stable for its entire service life, preventing unexpected changes over time.

The properties of nylon are directly linked to its moisture content. Think of it like a sponge. When it’s bone dry, it’s stiff and brittle. When it has some moisture, it becomes flexible and tough. The exact same principle applies to nylon at a molecular level. After we go through the critical process of drying the nylon for molding, we are left with a part that is in its most brittle state. If the part is put into service immediately, especially in a dry environment, it won’t have the toughness the design engineer was counting on.

At CavityMOLD, our job doesn’t end when the part is ejected from the mold. We think about the part’s entire lifecycle.

The Science of Re-moisturizing

The conditioning process stabilizes the nylon. In its "as-molded" dry state, the part will slowly absorb moisture from the atmosphere until it reaches equilibrium. As it absorbs this moisture, its dimensions will change slightly, and its mechanical properties will shift. This can take weeks or even months. This is unacceptable for precision components. Conditioning is simply a way to accelerate this process so the part is stable and has its final, intended properties before it ever leaves our facility. This guarantees that the part you test is the same as the part your customer uses years later.

How We Condition Parts

The most common method is to soak the parts in a temperature-controlled water bath. The temperature of the water and the duration of the soak are carefully calculated based on the part’s wall thickness and the specific grade of nylon. This allows the parts to absorb a controlled amount of moisture, typically between 1.5% and 2.5% by weight. This simple step transforms the part from brittle to tough.

| Property | As-Molded (Dry) | Conditioned (Moisture an Equilibrium) |

|---|---|---|

| Tensile Strength | High | Moderately Lower |

| Stiffness / Modulus | Very High | Lower |

| Impact Strength | Low | Very High |

| Flexibility / Elongation | Low | Very High |

| Dimensional Stability | Unstable (will change) | Stable |

By understanding and implementing post-molding conditioning, we ensure that your nylon parts deliver the full performance potential you expect. It’s the final step in a comprehensive process that guarantees robust, reliable components.

Conclusion

Mastering nylon injection molding requires a disciplined, four-stage approach. It starts with precise material drying, moves to intelligent mold design, and is executed with scientific process control. Finally, post-molding conditioning ensures long-term stability and toughness. We deliver superior parts by mastering every single step.