Are you struggling to select the right plastic for a demanding project? Picking the wrong material can lead to part failure, expensive re-tooling, and major project delays. Let me guide you through the world of engineering plastics so you can get it right the first time.

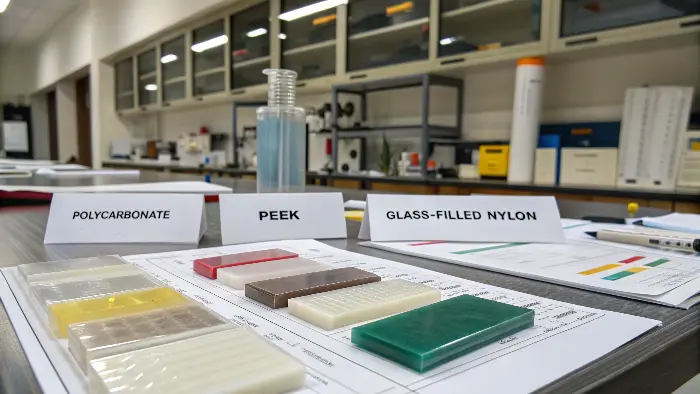

Choosing the best engineering plastic means matching the material to your specific application. You must first define your key performance requirements, such as mechanical stress, operating temperature, chemical exposure, and budget. Then, compare candidates like PEEK, Polycarbonate, and Nylon based on their data sheets. This methodical approach ensures you make a confident, data-driven decision for optimal performance.

Selecting the right material can feel like navigating a maze of acronyms and technical data sheets. It’s a critical step, and the pressure is on to get it right. But don’t worry. As someone who has been navigating this world for over a decade at CavityMold, I’ve learned how to simplify the process. Let’s break it down together, starting with where these impressive materials actually come from.

Where Do Engineering Plastics Come From?

Ever wonder where these high-strength polymers actually originate? It’s not as simple as just drilling for oil and getting a finished product. Understanding their source is key to grasping their unique properties and costs, but this information is often buried in complex technical jargon. Let’s clarify their journey.

Engineering plastics are synthetic polymers derived from petrochemicals, primarily crude oil or natural gas. The raw materials, called monomers, go through a chemical process called polymerization in large industrial plants. This process links them into long chains, forming the final polymer. Different monomers and processes create distinct plastics, like Polycarbonate (PC) or PEEK.

These materials aren’t "farmed" or found in nature; they are meticulously synthesized. The journey is a fascinating example of industrial chemistry that transforms simple molecules into some of the most robust materials we use today.

The Journey from Crude Oil to a Moldable Pellet

The process begins with refining crude oil to produce a fraction called naphtha. This naphtha is then "cracked" into simpler hydrocarbon molecules, which become the basic building blocks, or monomers. For example, Bisphenol A (BPA) and phosgene are the monomers used to create Polycarbonate.

These monomers are then introduced into a reactor vessel. Under specific conditions of temperature and pressure, and with the help of catalysts, they link together in a process called polymerization. This reaction creates long, repeating molecular chains—the polymer itself. The final polymer is then extruded, cooled, and chopped into the small pellets that we use in our injection molding machines at CavityMold. The structure formed during polymerization, either amorphous (messy, like PC) or semi-crystalline (orderly, like Nylon), heavily influences the final properties of the plastic, such as its transparency and melting behavior. It’s a precise science from start to finish.

Transforming Performance with Additives

Base polymers rarely have all the properties needed for a specific application. That’s where additives and fillers come in. These substances are compounded with the plastic pellets to enhance specific characteristics.

- Glass Fibers: Increase stiffness, strength, and heat distortion temperature. A very common choice for automotive parts.

- Carbon Fibers: Provide exceptional strength and stiffness with less weight than glass, plus electrical conductivity.

- Flame Retardants: Required for electronics and components that need to meet safety standards like UL 94.

- UV Stabilizers: Prevent degradation and discoloration in parts exposed to sunlight.

These additives turn a standard polymer into a high-performance, application-specific material.

Common Engineering Plastics and Their origins

| Plastic Name | Common Acronym | Key Monomer(s) | Primary Feedstock |

|---|---|---|---|

| Polycarbonate | PC | Bisphenol A, Phosgene | Crude Oil |

| Polyamide (Nylon) | PA6, PA66 | Caprolactam, Adipic Acid | Crude Oil |

| Acrylonitrile Butadiene Styrene | ABS | Acrylonitrile, Butadiene, Styrene | Crude Oil, Natural Gas |

| Polyether Ether Ketone | PEEK | Difluorobenzophenone | Crude Oil |

What Really Is the Best Plastic for Engineering Applications?

You’re asked to find the "best" plastic for a new product, but the term is so subjective it can be paralyzing. Choosing a material that isn’t the right fit can compromise the entire project. There’s no single "best" one, but there is always a best one for your specific application.

The "best" engineering plastic is the one that most cost-effectively meets all your project’s critical requirements. For unmatched transparency and impact strength, Polycarbonate is often best. For extreme temperature and chemical resistance, PEEK is a top choice. For a great balance of toughness and cost, glass-filled Nylon is excellent. The key is to define your needs first.

I remember a project for a client in the medical device industry. They initially asked for "the best, strongest plastic" for a new surgical tool handle. The temptation was to suggest PEEK because of its incredible strength and biocompatibility. However, after we discussed the specifics, we realized the tool was a single-use disposable. PEEK’s high cost and extreme temperature resistance were overkill. We ended up selecting a medical-grade ABS. It met all the strength requirements, was easily sterilized, and dramatically reduced the per-unit cost. This is a perfect example of why "best" is always relative.

Step 1: Define Your Non-Negotiables

Before you even look at a material data sheet, you have to create a checklist for your part. This list becomes your roadmap. It should answer these questions:

- Mechanical Load: Will it be under constant tension or compression? Will it face sudden impacts? This will guide your need for tensile strength versus impact strength.

- Thermal Environment: What is the maximum continuous operating temperature? Will it experience thermal cycling? This points you to materials with a high Heat Deflection Temperature (HDT).

- Chemical Exposure: Will the part come into contact with oils, acids, bases, or cleaning solvents? Chemical resistance is crucial to prevent degradation.

- Regulatory Needs: Does it need to be food-safe (FDA), biocompatible (USP Class VI), or flame retardant (UL 94)?

Step 2: Balancing Performance with Cost

Once you have a list of plastics that meet your non-negotiables, the next step is to balance performance with cost. A high-performance material like PEEK can cost over 20 times more than a workhorse like ABS. You have to ask if the added performance justifies the price. Always consider the total cost, which includes not just the raw material but also the processing. Some high-temperature plastics require special molding machine setups, which can add to the final part price. The goal is to find the material that does the job reliably without over-engineering and over-spending.

A Quick Comparison of Top Contenders

| Property | Polycarbonate (PC) | Nylon 6/6 (30% GF) | PEEK | ABS |

|---|---|---|---|---|

| Key Strength | Extreme Toughness | Balanced Strength & Cost | Temp/Chem Resistance | Good All-Rounder |

| Tensile Strength | Medium | High | Very High | Medium |

| Impact Strength | Very High | Medium | High | Medium |

| Max Use Temp | ~120 °C | ~150 °C | ~250 °C | ~80 °C |

| Relative Cost | Medium | Medium-Low | Very High | Low |

Is PTFE Considered an Engineering Plastic?

You’ve certainly heard of PTFE, probably by its famous brand name, Teflon™. Its unique non-stick and low-friction properties are legendary. But does it fit in the same category as structural plastics like Nylon or PEEK? This confusion can cause you to either overlook it or use it incorrectly.

Yes, PTFE (Polytetrafluoroethylene) is classified as a high-performance engineering plastic, or more specifically, a fluoropolymer. Its exceptional properties, including extreme chemical inertness, a very low friction coefficient, and a wide operating temperature range, make it vital for specialized engineering jobs. However, its lower mechanical strength means it’s not a direct substitute for load-bearing plastics like PEEK or Polycarbonate.

PTFE occupies a special place in the world of polymers. It’s an engineering plastic, but it’s a problem-solver for a very different set of problems than most other plastics. You don’t build a car bumper out of PTFE, but you absolutely use it for critical seals and bearings inside the engine. Its value lies in its unique surface properties and chemical stability.

What Makes PTFE Stand Out?

The magic of PTFE comes from its molecular structure. It’s made of a long chain of carbon atoms completely surrounded by fluorine atoms. The Carbon-Fluorine (C-F) bond is one of the strongest in organic chemistry. This structure gives PTFE its superstar properties:

- Extreme Chemical Inertness: It’s practically immune to all chemicals, acids, and bases. This makes it essential for seals and linings in the chemical processing industry.

- Lowest Coefficient of Friction: It’s one of the slipperiest substances known to man. Nothing sticks to it very well, which is great for non-stick coatings and low-friction bearings.

- Wide Temperature Range: It can perform reliably from cryogenic temperatures (-200 °C) up to about 260 °C.

Understanding PTFE’s Limitations

Despite its superpowers, PTFE isn’t invincible. Its primary drawback is its poor mechanical strength. It has low tensile strength and is susceptible to "creep," or cold flow, meaning it can deform over time when a load is applied. It is also quite soft and has poor abrasion resistance unless it’s filled with another material like glass or bronze. Finally, PTFE is not melt-processable in the way that common thermoplastics are. It can’t be easily injection molded. Instead, parts are typically made by compressing and sintering a powder, a process more like ceramics manufacturing. This makes part production more complex and costly.

PTFE vs. Polycarbonate: A Head-to-Head Comparison

| Property | PTFE (Polytetrafluoroethylene) | Polycarbonate (PC) |

|---|---|---|

| Primary Use | Low-friction, Chem-resist seals/bearings | High-impact structural parts, lenses |

| Tensile Strength | Very Low | Medium |

| Friction | Extremely Low | Medium |

| Chemical Resistance | Excellent | Poor (vulnerable to solvents) |

| Processing Method | Compression Molding / Sintering | Injection Molding / Extrusion |

| Relative Cost | High | Medium |

Which Engineering Plastic Is Truly the Toughest?

You need a part that can take a serious beating without cracking or shattering. The word "toughness" gets thrown around a lot, but it means something very specific in engineering. Choosing a plastic that is just "strong" might not be good enough, leading to unexpected and brittle failures in the field.

"Toughness" is a material’s ability to absorb energy and deform without fracturing. While other plastics might be stronger or stiffer, Polycarbonate (PC) is often considered the "toughest" common engineering plastic due to its phenomenal impact resistance. It can withstand significant, sudden blows without shattering, making it the top choice for protective gear, machine guards, and durable electronic enclosures.

Think about it this way: a ceramic plate is very strong and stiff (it can hold a lot of weight), but it’s not tough at all. Drop it, and it shatters. A rubber mallet, on the other hand, isn’t very strong, but it’s extremely tough. You can hit it with a hammer all day. Toughness is the ability to absorb that impact energy.

Toughness vs. Strength: What’s the Real Difference?

In materials science, strength and toughness are not the same thing.

- Strength (Tensile Strength): This is the maximum amount of pulling force a material can withstand before it starts to permanently stretch or break. A strong material resists being pulled apart.

- Toughness (Impact Strength): This is the ability of a material to absorb energy from a sudden blow. We often measure this with tests like the Notched Izod impact test, which tells us how much energy it takes to break a sample with a swinging pendulum.

A material like PEEK is incredibly strong, but a material like Polycarbonate is tougher. It gives a little and deforms to absorb the impact energy, whereas a very stiff and strong material might just snap.

The Champion of Impact Resistance: Polycarbonate

Polycarbonate’s reputation is built on its toughness. This is why it’s used for applications where safety and durability are paramount. Think of police riot shields, safety glasses, machine guards, and the "unbreakable" lenses in modern headlights. It maintains this incredible toughness over a wide range of temperatures, even below freezing. While it can be scratched and is susceptible to certain chemicals, no other transparent plastic comes close to its ability to absorb impact. For any application where the primary risk is sudden impact, PC should be at the top of your list. Other tough contenders include UHMW-PE (Ultra-High-Molecular-Weight Polyethylene), known for its combination of toughness and abrasion resistance, and certain grades of impact-modified Nylon.

Comparing the Toughness of Key Engineering Plastics

| Material | Notched Izod Impact Strength (J/m) | Key Characteristic | Typical Application |

|---|---|---|---|

| Polycarbonate (PC) | 600 – 850 | Extreme Impact Resistance, Clarity | Safety Goggles, Machine Guards |

| ABS | 150 – 300 | Good All-Around Toughness | LEGO Bricks, Electronic Housings |

| Nylon 6/6 (PA66) | 50 – 100 | Good Strength and Fatigue life | Gears, Fasteners |

| PEEK | 80 – 150 | High Strength and Temperature | Aerospace Components, Medical Implants |

Note: Values are typical and can vary greatly with grade and additives like glass fiber, which increases strength but reduces toughness.

Conclusion

Choosing the right engineering plastic isn’t about finding a single "best" material. It’s a methodical process of matching your specific application needs to the vast world of available polymers. By focusing on performance, environment, and cost, you can make a confident choice that ensures your project’s success.