Choosing between manufacturing processes can feel overwhelming, especially when a project’s success is on the line. Picking the wrong method for your plastic parts can lead to budget overruns and critical delays. You need a clear path to making the right decision for your specific application.

For early-stage development, low-volume runs, or projects needing high precision and speed, CNC machining is the ideal choice as it offers flexibility and quick turnarounds. When your design is finalized and you need to scale up for mass production, injection molding provides a highly cost-effective and repeatable solution. The best process depends entirely on your project’s stage, volume, and specific requirements.

The choice isn’t always black and white, though. A project manager’s success often hinges on understanding the subtle trade-offs between these two powerful methods. To make a truly informed decision, you need to look closer at how they compare in critical areas like cost, speed, material options, and design complexity. Let’s break it down, step-by-step, so you can see which method truly aligns with your project goals.

How Do The Fundamental Processes Actually Differ?

It’s easy to see CNC machining and injection molding as just two ways to get a plastic part. But if you don’t fully grasp their core differences, you can run into trouble. This lack of understanding can lead you to design parts that are needlessly difficult or expensive to manufacture. Let’s clarify exactly how each process works.

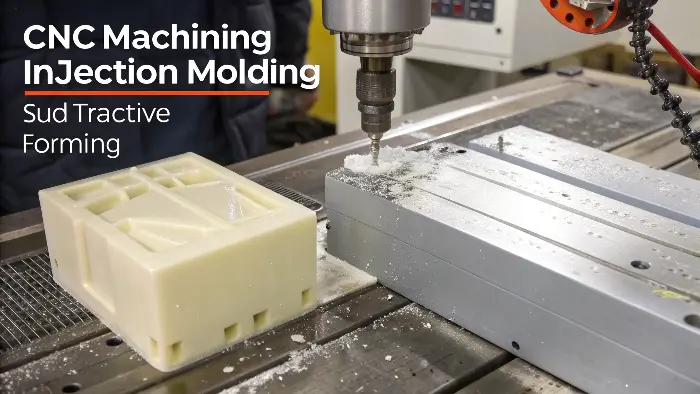

CNC machining is a subtractive process. It starts with a solid block of plastic and carves away material with a cutting tool to create the final shape. Injection molding is a forming process. It works by injecting molten plastic into a custom-made mold, or cavity, which then cools and solidifies into the desired part. This core difference—carving versus filling—is the source of all their other strengths and weaknesses.

To really get it, you have to visualize the journey from raw material to a finished component in both scenarios.

The CNC Machining Journey

Think of CNC machining as digital sculpting. The process is direct and linear.

- From Design to Code: It all begins with your 3D CAD model. We feed this model into CAM (Computer-Aided Manufacturing) software, which generates a set of instructions called G-code. This G-code is the roadmap that tells the machine precisely where to move, how fast to cut, and which tool to use.

- The Subtractive Step: A solid block of your chosen plastic is secured inside the CNC machine. The machine then follows the G-code, using spinning cutting tools like end mills and drills to meticulously remove material layer by layer. For more complex parts, a 5-axis machine can rotate both the tool and the part, allowing it to reach surfaces from multiple angles.

- The Result: What’s left is your final part. Because no custom tooling is needed, this process is incredibly fast for producing one or one hundred unique parts. The main byproduct is a pile of plastic chips, which is the material that has been "subtracted."

The Injection Molding Journey

Injection molding is a story of two halves: creating the tool, and then using it to mass-produce parts.

- The Mold is Everything: The biggest and most important step happens first: we machine a high-precision mold, often from steel or aluminum. This mold is the negative of your part. Creating it is a significant project in itself and represents the main upfront investment.

- The Molding Cycle: Once the mold is ready, it’s loaded into an injection molding machine. Plastic pellets are melted and then injected under immense pressure into the mold cavity. The machine holds this pressure, packs more material in to compensate for shrinkage, and then cools the mold.

- Ejection and Repetition: After a few seconds, the mold opens and ejector pins push the finished, solid part out. The mold closes again, and the cycle repeats. This cycle can take as little as 10-30 seconds, allowing for the production of thousands of identical parts in a single day.

| Feature | CNC Machining | Injection Molding |

|---|---|---|

| Process Type | Subtractive (material removal) | Forming (material filling) |

| Tooling | No custom tooling needed | Requires a custom-made mold |

| Initial Step | Program the machine with G-code | Design and manufacture a mold |

| Best For | Unique parts, prototypes | Identical, repeatable parts |

How Do Cost And Production Volume Affect Your Choice?

Your project has a strict budget, and you are rightly concerned about picking the more expensive manufacturing route. A miscalculation in the cost per part can quickly derail your financial planning, especially when you need to scale up production. Let’s look at how costs break down for both methods, so you can accurately forecast your expenses.

CNC machining has a higher cost per part but almost no upfront tooling investment. This makes it cost-effective for low volumes, from a single prototype up to a few hundred parts. Injection molding, on the other hand, has a very high upfront cost for the mold but an extremely low cost per part. This makes it the most economical choice for high-volume production, where the mold cost is spread across thousands of units.

The financial model for each process is fundamentally different. Your decision will almost always come down to the "break-even point." This is the production quantity where injection molding becomes cheaper than CNC machining.

The CNC Cost Structure

With CNC machining, the cost is simple and direct. The main cost drivers are:

- Machine Time: How long does it take the machine to carve your part? More complex parts mean more machine time and higher cost.

- Material: The cost of the solid block of plastic.

- Labor: The time for a skilled technician to set up the machine and program the job.

The cost per part stays relatively constant. Whether we are making the 10th part or the 200th part, the price is nearly the same because each one requires the same amount of machine time. There are very few economies of scale.

The Injection Molding Cost Structure

Here, the cost profile is heavily front-loaded.

- The Mold (Tooling): This is the single biggest expense. A mold can cost anywhere from a few thousand to over $50,000, depending on its complexity, the material used (aluminum for lower volumes, hardened steel for millions of parts), and the number of cavities.

- Setup and Part Cost: Once the mold is made, the other costs are minimal. The raw plastic pellets are inexpensive, and the machine cycle is so fast that labor and energy costs per part are fractions of a cent.

I remember a project with a client, let’s call him Alex, who needed 2,000 enclosures. With CNC, the quote was around $40 per unit, for a total of $80,000. For injection molding, the mold was $10,000, but the part cost was only $1.50. The total cost for molding was $10,000 + (2,000 x $1.50) = $13,000. It was a clear-cut decision. The break-even point in this case was around 260 units. Below that, CNC was cheaper. Above it, injection molding was the only logical choice.

| Quantity | CNC Total Cost (at $40/part) | Injection Molding Total Cost ($10,000 mold + $1.50/part) |

|---|---|---|

| 10 | $400 | $10,015 |

| 200 | $8,000 | $10,300 |

| 500 | $20,000 | $10,750 |

| 2,000 | $80,000 | $13,000 |

What About Design Complexity And Part Geometry?

You have designed a part with very specific angles and intricate details, but you’re not sure if it can even be made efficiently. Choosing a process that cannot handle your design’s complexity will force you into costly and time-consuming redesigns later. Let’s explore the design rules and limitations of each method to ensure your part is optimized for manufacturing from day one.

CNC machining excels at producing parts with highly complex geometries, deep pockets, and sharp internal corners, as it does not require draft angles. However, it can struggle with certain internal features a tool cannot reach. Injection molding is fantastic for creating complex external shapes but demands careful design considerations like draft angles, uniform wall thickness, and avoiding undercuts to ensure the part can be ejected cleanly from the mold.

The freedom you have as a designer is tied directly to the manufacturing process you choose.

Design Freedom with CNC Machining

CNC offers incredible freedom for certain types of complexity. Since the part doesn’t need to be pulled out of a cavity, many molding constraints disappear.

- No Draft Angles: You can design perfectly vertical walls (90-degree angles), which is impossible in molding.

- Complex Surfaces: Modern 5-axis CNC machines can create incredibly organic and complex surfaces by moving the tool along X, Y, and Z axes while also rotating the part and the tool head.

- Undercuts and Pockets: Deep pockets or features on multiple faces of the part are relatively straightforward.

However, CNC has its own rules. The primary limitation is tool access. If a cutting tool can’t physically reach a surface, it can’t cut it. Also, any internal corner will have a radius that matches the radius of the cutting tool used. You can’t achieve a perfectly sharp internal corner.

Design for Manufacturability (DFM) for Injection Molding

For injection molding, designing for manufacturability is not just a good idea—it’s essential. This is where we spend a lot of time advising our partners. A successful molded part must follow several key rules:

- Draft Angles: All surfaces parallel to the direction the mold opens must be slightly angled (typically 1-3 degrees). This "draft" allows the part to be pushed out without scraping against the mold walls.

- Uniform Wall Thickness: The walls of the part should be as uniform in thickness as possible. If one area is much thicker than another, it will cool slower, causing it to shrink and create ugly sink marks or warp the part.

- Avoid Undercuts: An undercut is any feature that would prevent the part from being pulled straight out of the mold. These require expensive "side-actions" or "sliders" in the mold. If an undercut can be designed out, you can save thousands on tooling.

- Radii on Corners: Sharp corners create stress points in the part and are difficult to machine into the mold. Adding a generous radius to all corners makes the part stronger and the mold more durable.

| Design Feature | CNC Machining | Injection Molding |

|---|---|---|

| Internal Corners | Limited by tool radius | Can be sharp (but creates stress) |

| Draft Angles | Not required | Essential for part ejection |

| Wall Thickness | Can vary widely | Must be kept uniform |

| Undercuts | Possible with 5-axis machining | Requires complex, costly mold actions |

Which Process Offers Better Speed And Material Options?

You’re on a tight deadline and need parts fast, but they also have to be made from a specific high-performance plastic. Choosing the slower process or one that can’t handle your required material could mean missing a critical launch date. Let’s compare the speed and material flexibility of both processes to see which aligns with your timeline and performance needs.

For pure speed on initial parts, CNC machining is the undisputed winner. You can have a physical part in your hands within days, as no mold is needed. Injection molding has a long initial lead time of weeks or even months to create the mold, but part production is extremely fast afterward. CNC offers a wide range of machinable engineering plastics, while injection molding has a massive library of moldable resins, including custom compounds.

The trade-off between speed and material choice is a classic project management puzzle. One process gets you there fast, the other gives you more options for the long run.

The Speed and Lead Time Factor

This is often the most critical factor in early development.

- CNC Machining is for Rapid Prototyping: If you need to test a design tomorrow, CNC is your only option. We can often take a CAD file and ship a finished part in 24 to 72 hours. I had a client who needed to validate a new snap-fit mechanism. We CNC-machined five different design variations in less than a week. This allowed them to physically test and approve the final design before committing to an expensive production mold.

- Injection Molding is for Production Speed: The bottleneck here is building the mold, which can take anywhere from 4 to 12 weeks. But once that mold is finished and tested, you can produce parts at an incredible speed. Cycle times are often under 30 seconds, meaning you can get thousands of parts per day. It’s a long wait followed by extremely rapid output.

The Material Selection Factor

The type of plastic you can use is also very different.

- CNC Materials (Stock Shapes): CNC machining starts with a solid block or rod of plastic. This means you’re limited to materials available in these "stock" forms. The good news is that this includes most common engineering-grade plastics like ABS, Polycarbonate (PC), Nylon, Delrin (POM), and high-performance materials like PEEK and Ultem. A huge advantage is that a CNC-machined prototype will have the true mechanical properties of the bulk material, making it perfect for functional testing.

- Injection Molding Materials (Resins): Injection molding uses plastic pellets, or resins. The selection is almost limitless. Nearly every thermoplastic can be injection molded. Furthermore, you can use specialized compounds with additives like glass fibers for strength, UV stabilizers for outdoor use, or lubricants for low-friction parts. You can also match colors precisely. This gives you ultimate control over the final part’s properties and appearance.

| Aspect | CNC Machining | Injection Molding |

|---|---|---|

| Initial Lead Time | Very Short (1-5 days) | Very Long (4-12 weeks) |

| Per-Part Speed | Slow (minutes to hours) | Very Fast (seconds) |

| Material Form | Solid Block/Rod | Pellets/Resin |

| Material Variety | Wide (most engineering plastics) | Massive (most thermoplastics, composites) |

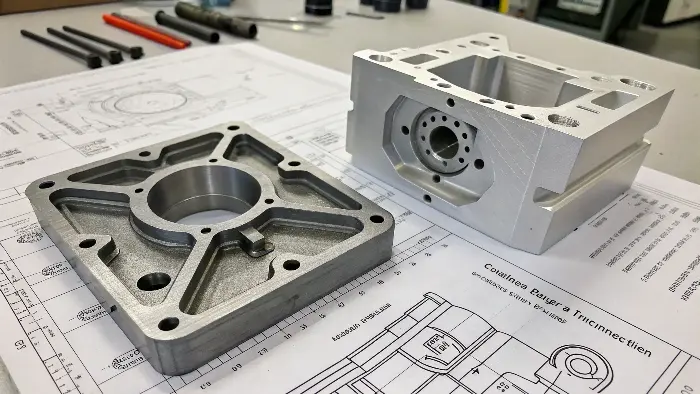

What About Tolerances And Surface Finish Quality?

Your plastic part has critical features that must fit perfectly with other components, and a professional aesthetic is essential for the final product. Poor tolerances can lead to assembly failures and functional problems, while a bad surface finish can ruin the perceived quality and value of your product. Let’s look closely at the precision and finish you can expect from both methods.

CNC machining generally offers tighter dimensional tolerances straight from the machine, holding critical features as close as ±0.025 mm. Its surface finish is defined by visible tool marks, which can be improved with post-processing. Injection molding provides excellent repeatability, and the surface finish is a direct replica of the mold’s cavity surface, which can be polished to a mirror-like sheen or given a specific texture.

For a project manager like Alex, who works with components for consumer electronics, controlling these two factors is non-negotiable.

Precision and Tolerances

This is about hitting your dimensional targets accurately.

- CNC Machining: This process is known for its high accuracy. A well-calibrated CNC machine can produce parts with extremely tight tolerances. This makes it the go-to process for jigs, fixtures, and functional prototypes where an exact fit is critical on the very first part. The precision is limited only by the accuracy of the machine itself and the rigidity of the setup.

- Injection Molding: The story here is more about consistency than initial accuracy. While good tolerances (e.g., ±0.1 mm) are achievable, they are affected by many variables: the plastic’s shrink rate, cooling time, injection pressure, and the mold’s design. The magic of injection molding is that once these variables are locked in, the 10,000th part will be virtually identical to the 10th part. Achieving tight tolerances consistently requires a deep understanding of mold design and process control—this is where partnering with an experienced molder is critical.

Surface Finish Quality

This is all about the look and feel of the part.

- CNC Machining: The default "as-milled" finish will always have very fine, often circular, lines left by the cutting tool. The quality of this finish depends on the tool size, cutting speed, and material. While this mechanical finish is fine for many functional parts, it can be improved through secondary operations like bead blasting (for a uniform matte look), sanding, or polishing, but these add time and cost.

- Injection Molding: The surface finish of the part is a direct copy of the finish on the inside of the mold cavity. This gives you incredible control. We can prepare the mold surface to meet specific industry standards, such as those from the Society of the Plastics Industry (SPI). For example, an "SPI-A1" finish on the mold results in a part with a mirror-like, optically clear surface. We can also give the mold a textured finish by bead blasting or chemical etching. For a consumer product, this means the desired finish is created automatically on every part, with no extra steps.

| Attribute | CNC Machining | Injection Molding |

|---|---|---|

| Typical Tolerance | Tighter (e.g., ±0.025 mm to ±0.125 mm) | Good, but depends on process control (e.g., ±0.1 mm) |

| Consistency | Good per part, but can vary with each setup | Excellent part-to-part repeatability |

| Surface Finish | Shows tool marks (can be post-processed) | Replicates mold surface (can be textured, polished) |

| Control | Controlled by machine path and tool | Controlled by mold surface finish (SPI standards) |

Conclusion

The decision between CNC machining and injection molding comes down to an honest assessment of your project’s goals. CNC is your solution for speed, flexibility, and precision in low volumes. Injection molding is the champion of scalability, low part cost, and design options for mass production.