Struggling to get your thin-wall parts right? Warping, short shots, and cracks are probably driving you crazy and costing you a ton of money and time. But what if you could master the key principles that ensure success every single time? It’s not as hard as you might think.

Success in thin-wall injection molding hinges on a holistic approach. You must carefully select materials with high flow rates, design parts with uniform wall thickness and proper gating, and use molds built for high pressure and fast cooling. Optimizing the injection process with high speeds and pressures is also absolutely critical. It’s a combination of material, design, and process working together.

Getting thin-wall parts right feels like a huge win. I’ve been in this business for over a decade, and I still get a kick out of seeing a perfectly formed, paper-thin container pop out of the mold. But I’ve also seen the other side—the frustrating projects that seem to go nowhere. The key isn’t one single secret; it’s about getting a few fundamental things right from the very beginning. Let’s walk through them one by one, starting with the material itself.

How Do You Choose the Right Material for Thin Wall Injection Molding?

Picking the wrong plastic for a thin-wall part is a recipe for disaster. I’ve seen it happen. The material won’t flow, parts come out brittle, and the entire project just stalls. So, I want to show you a simple way to evaluate materials based on what really matters: properties, how it processes, and final performance.

For thin-wall molding, you have to prioritize materials with a high Melt Flow Index (MFI) or Melt Flow Rate (MFR), like certain grades of polypropylene (PP), polyethylene (PE), or specialized ABS and polycarbonate (PC). These materials flow like water into thin sections before they can freeze off. You also have to consider the material’s strength and stiffness to prevent warping and ensure the part actually works.

Choosing the right material is probably the most important decision you’ll make. It sets the foundation for everything else. If the material can’t physically fill the mold cavity, nothing else you do will matter. I remember a project for a thin-walled electronics housing where we struggled for weeks with short shots. We switched from a standard ABS to a high-flow grade, and bam—it solved all our problems overnight. It was a real game-changer and a lesson I never forgot.

Breaking Down Material Choice

When we look at materials, we’re balancing a few key things. It’s a classic engineering trade-off.

-

Flowability is King: The most critical property is the Melt Flow Index (MFI). A higher MFI means the plastic is less viscous—it flows more easily. For thin walls, you need that plastic to race through the mold and fill every tiny corner before it cools and solidifies. Think of it like trying to pour honey versus water into a tiny tube; you want the water.

-

Strength and Stiffness: Here’s the trade-off. Often, materials with the highest flow rates aren’t the strongest. You need to find a balance. The part has to be strong enough to do its job and stiff enough not to warp into a potato chip as it cools. This is where talking to your material supplier—or a mold maker like us—is super helpful. We can guide you to grades that offer the best of both worlds.

-

Processing Window: Some materials are just more forgiving than others. They have a wider processing window for temperature and pressure, which makes life on the production floor a lot easier.

Here’s a quick look at some common choices:

| Material | Key Advantages for Thin Wall | Potential Downsides |

|---|---|---|

| Polypropylene (PP) | Excellent flow (high MFI), low cost, good chemical resistance. | Lower stiffness, can be prone to warping. |

| Polyethylene (PE) | Great flow, very tough and flexible, inexpensive. | Very low stiffness, not for structural parts. |

| ABS | Good balance of flow, stiffness, and impact strength. | Can be sensitive to processing parameters. |

| Polycarbonate (PC) | High strength and heat resistance, very tough. | More difficult to process, requires high temps. |

What Are the Key Mold Design Considerations for Thin Wall Parts?

So you’ve picked your material. Great. But now you have to design a mold that can handle it. A perfect part design can be completely ruined by a poorly thought-out mold. You end up with uneven filling, crazy high stress in the part, and pieces that just won’t eject properly. Let’s break down the mold features that are totally non-negotiable for thin-wall success.

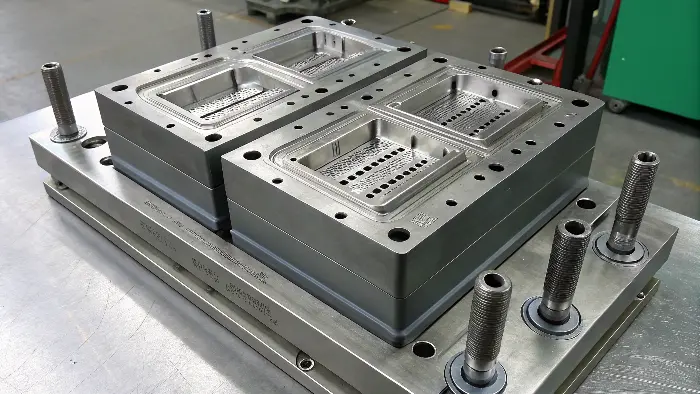

A successful thin-wall mold needs a robust gating system—like fan gates or, even better, a hot runner system—to ensure rapid, even filling. It must have an extremely efficient and balanced cooling system to slash cycle times and prevent warpage. Also, proper venting is crucial to let trapped air escape, which prevents burn marks and incomplete fills. The mold itself has to be tough.

I can’t stress this enough: the mold is not the place to cut corners on a thin-wall project. It’s the heart of the whole operation. We once had a client bring us a mold they had made elsewhere for a thin food container. It was a mess. The cooling was uneven, and the venting was an afterthought. They were getting maybe 50% good parts. We ended up having to do a major rework—adding vents and re-drilling cooling lines—just to make it functional. Doing it right the first time saves so much pain.

Diving Deeper into Mold Design

Let’s get into the nitty-gritty of what makes a great thin-wall mold.

-

Gating is Everything

The gate is where the plastic enters the part cavity, and for thin parts, its design is critical. You need to get a large volume of plastic in very, very quickly. A tiny pinpoint gate just won’t work. We often use fan gates or tab gates that spread the flow out. Even better is a hot runner system. Hot runners keep the plastic molten all the way to the part, which dramatically improves flow and reduces pressure loss. It’s a bigger upfront investment, but for high-volume thin-wall parts, it almost always pays for itself in reduced cycle times and material waste. -

Cooling, Cooling, and More Cooling

With thin-wall molding, the cycle time is mostly cooling time. The faster you can cool the part evenly, the faster you can make the next one. Uneven cooling is the number one cause of warpage. We spend a ton of time designing cooling channels that are placed strategically and conform to the part’s shape. Sometimes we’ll even use special high-conductivity mold materials like beryllium-copper in critical areas to pull heat out even faster. -

Venting and Ejection

When plastic shoots into a mold at high speed, the air inside has to go somewhere. If it can’t get out, it gets compressed, heats up, and burns the plastic. Or, it creates a pocket of pressure that stops the plastic from filling the mold completely (a short shot). Vents are tiny channels on the mold’s parting line that let air out but are too small for plastic to escape. For ejection, thin parts are delicate and have a huge surface area that can stick to the mold. You need plenty of ejector pins, carefully placed to push the part out without marking or deforming it.

What Kind of Injection Molding Machine Do You Need for Thin Wall Applications?

Okay, you’ve got a great material and a brilliantly designed mold. But if you put that mold in a machine that can’t keep up, you’re still going to have problems. The machine might not be fast enough or powerful enough, leading to inconsistent parts and painfully slow production. So, let’s look at the specific machine specs you absolutely need for thin-wall molding.

For thin-wall molding, you need a high-performance injection molding machine. The key specs are high injection speed and high injection pressure capabilities. You also need a fast-response servo-valve and excellent shot-to-shot consistency. A machine with a hydraulic accumulator—which is like a power booster for injection—is a huge advantage. And don’t forget the clamping force!

Think of the machine as the engine. You can have the best car in the world (the mold), but if you put a lawnmower engine in it, you’re not going to win any races. We often advise our clients on machine selection. For serious thin-wall applications, especially in packaging or medical, we almost always recommend a modern all-electric or hybrid machine. The precision, speed, and repeatability are just on another level compared to older hydraulic machines. The control you get is phenomenal, and that’s what you need for these demanding jobs.

Key Machine Specifications

Let’s break down what to look for on the machine’s spec sheet.

-

Injection Speed & Pressure

This is non-negotiable. You need to fill the mold in a fraction of a second—sometimes as fast as 0.1 seconds! This requires a machine capable of very high injection speeds (mm/sec) and the pressure to back it up. The goal is to get the plastic to the farthest point of the cavity before it has a chance to freeze. This is often called "injection velocity." A machine with a hydraulic accumulator can deliver that short, intense burst of speed and pressure needed. -

Clamping Force

All that injection pressure inside the mold cavity is trying to force the two halves of the mold apart. The machine’s clamp has to be strong enough to hold it shut. The required clamp force is basically the injection pressure multiplied by the part’s projected area. For thin-wall parts, the injection pressure is very high, so you often need a machine with a higher clamp tonnage than you’d expect for such a small, light part. -

Precision and Repeatability

All-electric machines really shine here. They use servo motors instead of hydraulics, giving you incredibly precise control over every aspect of the process—injection speed, pressure, screw position, everything. This means that shot #1 is identical to shot #10,000. That consistency is gold when you’re trying to hold tight tolerances on a thin-walled part.

| Machine Spec | Why It’s Critical for Thin Wall | What to Look For |

|---|---|---|

| Injection Speed | Fills the cavity before the plastic freezes. | High (e.g., >500 mm/s). Accumulator is a plus. |

| Injection Pressure | Overcomes resistance to flow in thin sections. | High (e.g., >25,000 PSI or 1700 bar). |

| Clamping Force | Keeps the mold shut against high cavity pressure. | Sufficient tonnage for the part’s projected area. |

| Control System | Ensures shot-to-shot consistency and repeatability. | Modern, fast-response controller. All-electric is best. |

How Do You Systematically Optimize Process Parameters for Thin Wall Molding?

You’ve done it all. You have the right material, a killer mold, and a top-tier machine. But your parts are still not quite perfect. This is where the real craft comes in. Just randomly tweaking settings is a great way to waste a lot of time and material. What you need is a systematic approach to dial in your process for flawless parts.

Optimizing the process involves a systematic approach, not just guesswork. The most critical parameters are injection speed, injection pressure, melt temperature, and mold temperature. You generally need very high injection speeds to fill the part, and high packing pressures to minimize shrinkage. A slightly higher melt and mold temperature can also improve flow, but it’s a balancing act.

Honestly, this is my favorite part of the job. It’s like being a detective. You look at the part, see the defect—a little warp here, a sink mark there—and you know which knob to turn. But it comes from experience and a methodical process. I always tell new engineers: change one thing at a time! If you change three things and it gets better, you have no idea which change actually helped. Be patient, be systematic, and take good notes.

A Step-by-Step Tuning Process

You can get super scientific with a full Design of Experiments (DOE), but for most situations, a simplified, logical approach works wonders.

-

The Big Four Parameters

Focus on the variables that have the biggest impact:- Injection Speed: This is usually your primary tool. Your goal is to fill the mold about 95-98% full on the first stage of injection, as fast as possible without causing flash or burn marks.

- Pack/Hold Pressure: After the mold is full, you switch to a second, lower pressure stage. This "packs" out the part, pushing in a little more material to compensate for shrinkage as it cools. This is your main tool for fighting sink marks and voids.

- Melt Temperature: A hotter melt flows more easily, but too hot and you can degrade the material or increase your cooling time. It’s a fine balance.

- Mold Temperature: A warmer mold also helps the plastic flow farther before freezing. But again, too warm and your cycle times will be too long, and the part might be too soft to eject without deforming.

-

A Simple Troubleshooting Guide

Here’s a quick cheat sheet for common problems. It’s not exhaustive, but it’s a great starting point.

| Problem | Primary Cause | What to Try First |

|---|---|---|

| Short Shot (Incomplete Part) | Plastic freezes before the mold is full. | Increase Injection Speed. Then try increasing Melt/Mold Temp. |

| Warpage | Uneven cooling or internal stress. | Check for differences in mold half temps. Adjust Pack Pressure/Time. |

| Flash (Plastic leaks out) | Clamp force too low or injection speed too high. | Reduce Injection Speed/Pressure. Check if Clamp Force is sufficient. |

| Sink Marks | Not enough material packed into the part. | Increase Pack Pressure or Pack Time. |

This final stage is where science meets art. Sometimes a tiny 2°C change in mold temperature or a 50 PSI tweak in pack pressure can be the difference between a perfect part and a reject.

Conclusion

So, there you have it. Success with thin-wall parts isn’t some dark magic. It’s about building a solid foundation with four key pillars: the right material, a smart mold design, a capable machine, and a dialed-in process. Get these four things right, and you’ll be molding perfect, cost-effective parts every time. Master Molding Right—that’s what we’re all about.